How does the impact resistance of guide bushing ensure that it maintains structural integrity and normal function when engineering machinery is subjected to sudden external forces?

Release Time : 2025-05-08

In the complex and changeable working environment of engineering machinery, sudden external forces are like hidden "killers", threatening the structural integrity and normal function of the equipment at all times. As a key component, guide bushing has become an important line of defense to ensure the stable operation of engineering machinery with its excellent impact resistance.

The impact resistance of guide bushing first benefits from its carefully selected materials. Common high-quality guide bushings will use metal materials with high strength and toughness, such as certain special alloy steels. These materials have undergone special smelting and processing technology, and their internal structure is dense and uniform, which can withstand large impact loads without breaking or deformation. The alloy elements in alloy steel can refine the grains, improve the strength and hardness of the material, and enhance its toughness, so that when facing sudden external forces, guide bushing can not only resist the extrusion of impact force, but also absorb part of the energy through its own elastic deformation, avoiding structural damage due to stress concentration.

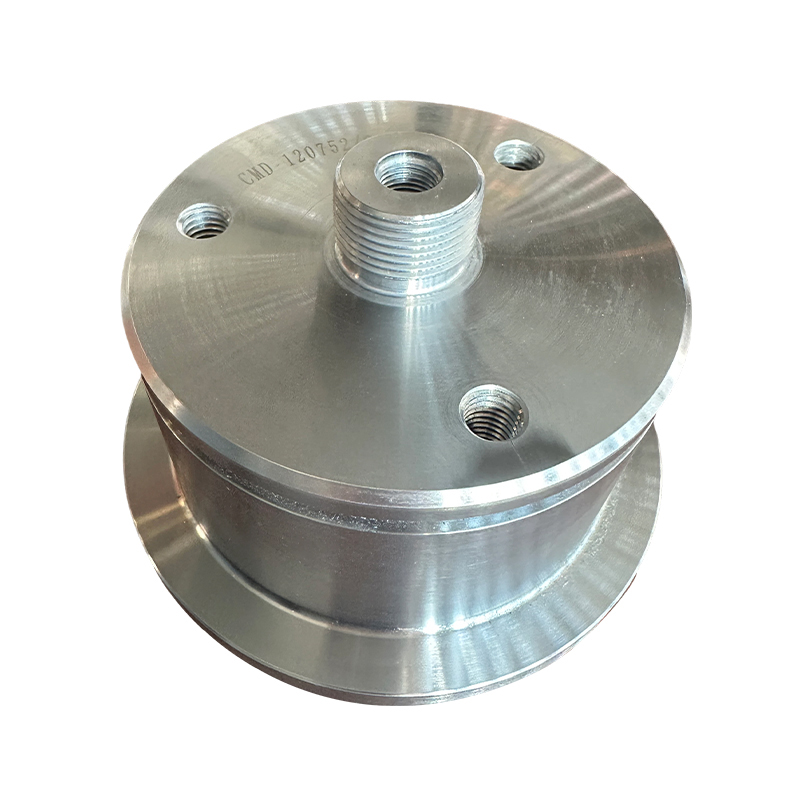

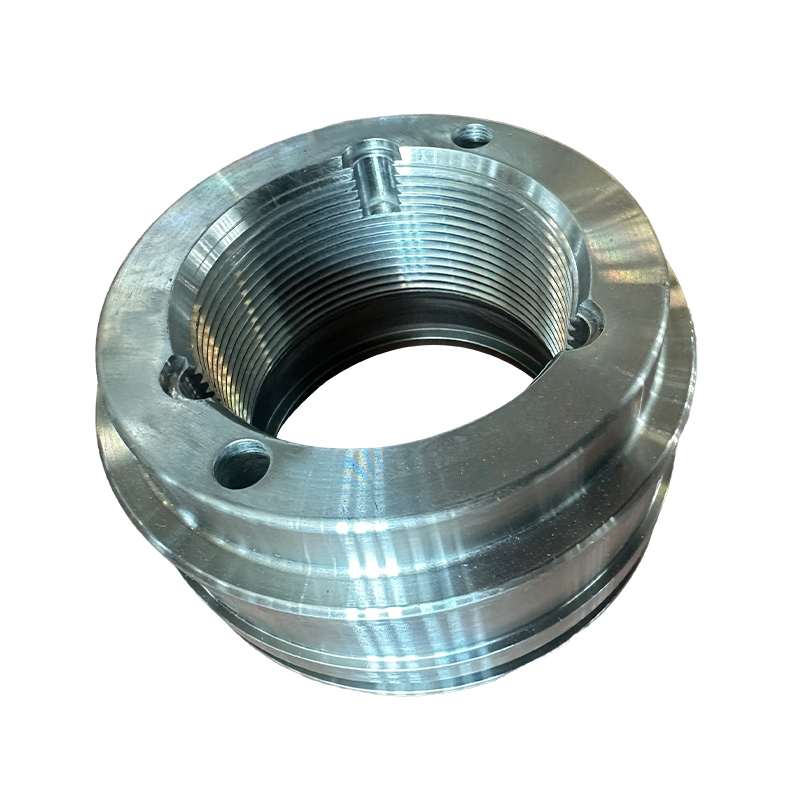

The unique structural design is another key factor in the impact resistance of guide bushing. The shape and size of guide bushings are precisely calculated and optimized to adapt to different working scenarios and stress conditions. Some guide bushings adopt a thickened wall design to increase their ability to resist impact. At the same time, the inner and outer wall surfaces of guide bushings are specially treated, such as surface hardening, to form a hard and wear-resistant surface layer, which can effectively resist friction and wear during impact. In addition, the installation method of guide bushings also has an important influence on their impact resistance. Reasonable installation structure can ensure that the guide bushings are closely matched with other parts of the construction machinery, disperse the impact force, and avoid damage to the guide bushings due to excessive local force.

Advanced manufacturing technology provides a solid guarantee for the impact resistance of guide bushings. During the processing, high-precision CNC machine tools and advanced processing technology are used to ensure that the dimensional accuracy and shape accuracy of guide bushings reach an extremely high level. Accurate dimensions can ensure that the matching clearance between guide bushings and other components is reasonable, reducing vibration and impact caused by excessive clearance. At the same time, the heat treatment process in the manufacturing process is also crucial. Through appropriate heat treatment processes such as quenching and tempering, the internal structure of the guide bushing material can be adjusted to obtain the best mechanical properties. Quenching can improve the hardness and strength of the guide bushing, while tempering can eliminate the internal stress generated during the quenching process and improve the toughness and impact resistance of the guide bushing.

In order to further improve the impact resistance of the guide bushing, some high-end guide bushings also use special technologies and designs. For example, some guide bushings are equipped with a buffer structure inside. When subjected to sudden external force impact, the buffer structure can undergo elastic deformation, absorb and disperse the impact energy, thereby reducing the impact on the main body of the guide bushing. Some guide bushings also use self-lubricating technology to form a lubricating film on the surface of the guide bushing, which reduces friction and wear while also alleviating the impact of the impact force to a certain extent. This self-lubricating technology can not only increase the service life of the guide bushing, but also ensure the smooth movement of the guide bushing under the action of sudden external forces and maintain its normal function.

In addition, strict quality inspection is an important link to ensure that the impact resistance of the guide bushing meets the requirements. During the production process of guide bushing, multiple quality inspection processes will be carried out, including appearance inspection, dimension measurement, hardness test, impact test, etc. Through these inspection methods, quality problems of guide bushing can be discovered in time, and unqualified products can be eliminated and improved. Only guide bushings that have undergone strict quality inspection can be applied to construction machinery to provide reliable protection for equipment when it is subjected to sudden external forces.

Guide bushings have comprehensively improved their impact resistance through high-quality material selection, unique design structure, advanced manufacturing process, special technical application and strict quality inspection. When construction machinery is subjected to sudden external forces, guide bushings can rely on these advantages to maintain structural integrity and normal functions, and escort the stable operation of construction machinery.

The impact resistance of guide bushing first benefits from its carefully selected materials. Common high-quality guide bushings will use metal materials with high strength and toughness, such as certain special alloy steels. These materials have undergone special smelting and processing technology, and their internal structure is dense and uniform, which can withstand large impact loads without breaking or deformation. The alloy elements in alloy steel can refine the grains, improve the strength and hardness of the material, and enhance its toughness, so that when facing sudden external forces, guide bushing can not only resist the extrusion of impact force, but also absorb part of the energy through its own elastic deformation, avoiding structural damage due to stress concentration.

The unique structural design is another key factor in the impact resistance of guide bushing. The shape and size of guide bushings are precisely calculated and optimized to adapt to different working scenarios and stress conditions. Some guide bushings adopt a thickened wall design to increase their ability to resist impact. At the same time, the inner and outer wall surfaces of guide bushings are specially treated, such as surface hardening, to form a hard and wear-resistant surface layer, which can effectively resist friction and wear during impact. In addition, the installation method of guide bushings also has an important influence on their impact resistance. Reasonable installation structure can ensure that the guide bushings are closely matched with other parts of the construction machinery, disperse the impact force, and avoid damage to the guide bushings due to excessive local force.

Advanced manufacturing technology provides a solid guarantee for the impact resistance of guide bushings. During the processing, high-precision CNC machine tools and advanced processing technology are used to ensure that the dimensional accuracy and shape accuracy of guide bushings reach an extremely high level. Accurate dimensions can ensure that the matching clearance between guide bushings and other components is reasonable, reducing vibration and impact caused by excessive clearance. At the same time, the heat treatment process in the manufacturing process is also crucial. Through appropriate heat treatment processes such as quenching and tempering, the internal structure of the guide bushing material can be adjusted to obtain the best mechanical properties. Quenching can improve the hardness and strength of the guide bushing, while tempering can eliminate the internal stress generated during the quenching process and improve the toughness and impact resistance of the guide bushing.

In order to further improve the impact resistance of the guide bushing, some high-end guide bushings also use special technologies and designs. For example, some guide bushings are equipped with a buffer structure inside. When subjected to sudden external force impact, the buffer structure can undergo elastic deformation, absorb and disperse the impact energy, thereby reducing the impact on the main body of the guide bushing. Some guide bushings also use self-lubricating technology to form a lubricating film on the surface of the guide bushing, which reduces friction and wear while also alleviating the impact of the impact force to a certain extent. This self-lubricating technology can not only increase the service life of the guide bushing, but also ensure the smooth movement of the guide bushing under the action of sudden external forces and maintain its normal function.

In addition, strict quality inspection is an important link to ensure that the impact resistance of the guide bushing meets the requirements. During the production process of guide bushing, multiple quality inspection processes will be carried out, including appearance inspection, dimension measurement, hardness test, impact test, etc. Through these inspection methods, quality problems of guide bushing can be discovered in time, and unqualified products can be eliminated and improved. Only guide bushings that have undergone strict quality inspection can be applied to construction machinery to provide reliable protection for equipment when it is subjected to sudden external forces.

Guide bushings have comprehensively improved their impact resistance through high-quality material selection, unique design structure, advanced manufacturing process, special technical application and strict quality inspection. When construction machinery is subjected to sudden external forces, guide bushings can rely on these advantages to maintain structural integrity and normal functions, and escort the stable operation of construction machinery.