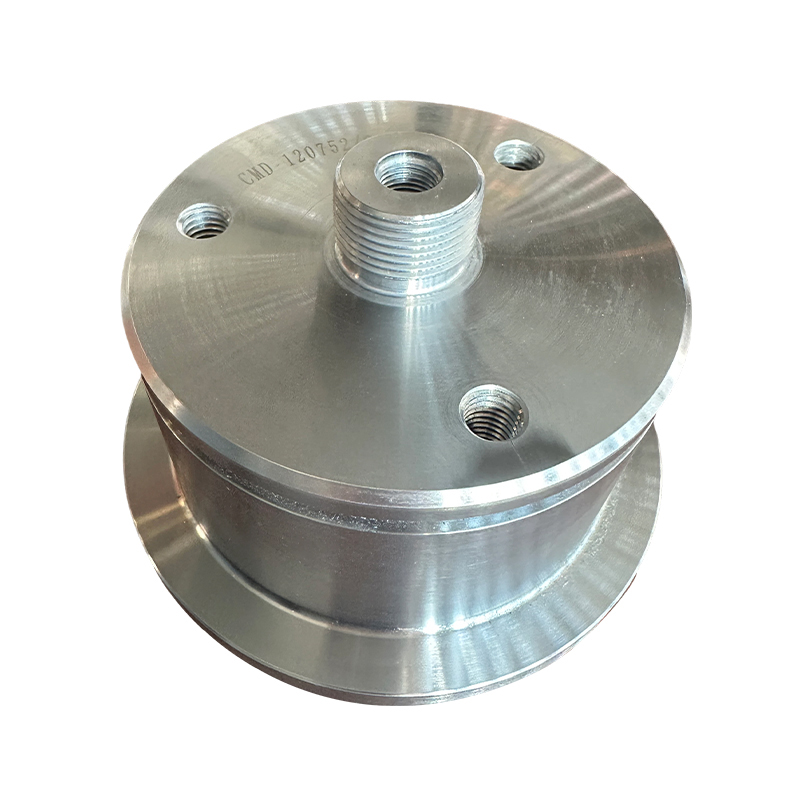

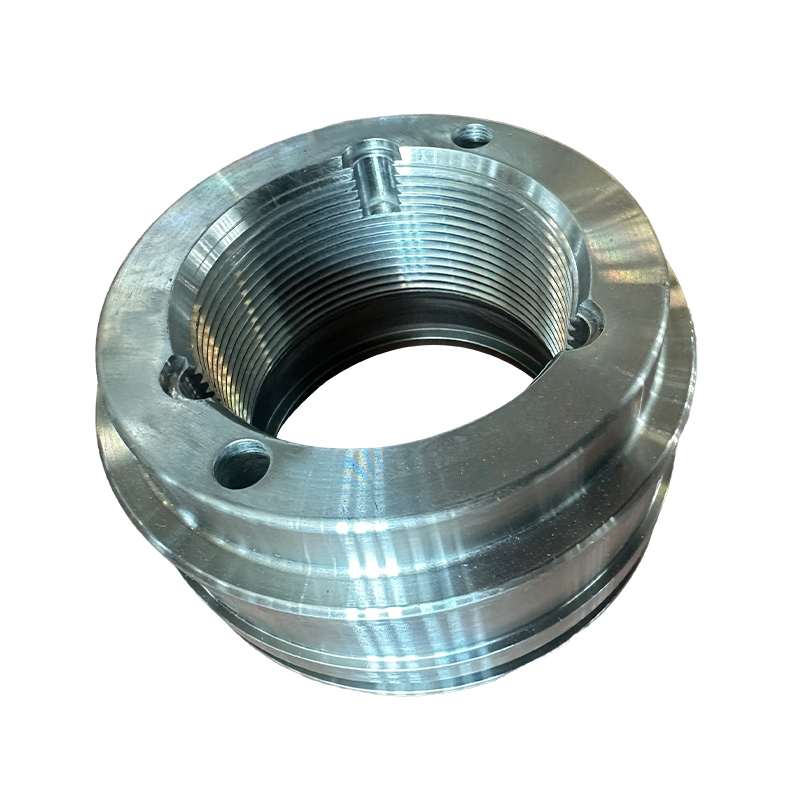

How can the high-strength alloy material of construction machinery parts piston maintain structural stability and wear resistance under high temperature and high pressure environment?

Release Time : 2025-07-16

The high-strength alloy material used in construction machinery parts piston is the core guarantee for coping with high temperature and high pressure environment. Its special composition ratio and microstructure allow construction machinery parts piston to maintain structural stability and excellent wear resistance under extreme working conditions. This material is not a simple application of a single metal, but a performance system that adapts to harsh environments is constructed through the synergistic effect of multiple alloys.

The main components in the alloy material are carefully selected, usually containing metal elements with high temperature stability. These elements are not easy to change the crystal structure at high temperature and can maintain the overall rigidity of the alloy. When the construction machinery parts piston is in the high temperature environment of the combustion chamber, the stable lattice structure formed by these elements resists the softening trend caused by the increase in temperature, ensuring that the construction machinery parts piston will not be deformed due to high temperature, laying the foundation for structural stability.

In terms of coping with high pressure, the density of the alloy material plays a key role. Through a special smelting process, the pores and impurities inside the alloy are greatly reduced, forming a tight molecular arrangement. This dense structure can evenly disperse the high-pressure impact force that the construction machinery parts piston is subjected to during operation, avoid cracks or fractures caused by local stress concentration, and allow the construction machinery parts piston to maintain its intact shape when repeatedly subjected to high-pressure loads.

The realization of wear resistance depends on the distribution of hard phases in the alloy. The wear-resistant elements added to the material will form fine and hard particles during the solidification process. These particles are evenly distributed in the alloy matrix, like embedded "wear-resistant points". When the construction machinery parts piston and the cylinder liner move relative to each other, these hard particles can withstand the main friction loss, reduce the wear of the matrix, and protect the surface from scratches, thereby extending the service life of the construction machinery parts piston.

Anti-oxidation performance at high temperatures is also an important support for structural stability. The anti-oxidation elements added to the alloy will form a dense oxide film on the surface of the construction machinery parts piston. This film can prevent the high-temperature gas from further eroding the construction machinery parts piston material and prevent the material from becoming brittle or peeling off due to oxidation. Even in long-term high-temperature operation, this oxide film can continue to play a protective role and maintain the structural integrity of the construction machinery parts piston.

The thermal expansion coefficient of the alloy material is precisely controlled to match the expansion characteristics of the cylinder liner material. In a high-temperature environment, the construction machinery parts piston and the cylinder liner will expand at the same time, but the expansion amplitude of the two will remain coordinated, and the matching clearance will not be abnormal due to excessive expansion differences, which not only avoids the jamming caused by too small a clearance, but also prevents air leakage and wear caused by too large a clearance, indirectly ensuring structural stability and wear resistance.

In addition, the heat treatment process of the alloy material further enhances its comprehensive performance. Through quenching, tempering and other processes, the internal stress of the alloy is eliminated and the grain structure is refined, which not only improves the strength and hardness of the material, but also retains a certain toughness, allowing the construction machinery parts piston to resist deformation and withstand impact loads under high temperature and high pressure, while maintaining the wear resistance of the surface, and fully adapting to the harsh working environment of construction machinery.

It is the synergistic effect of the characteristics of these materials and the process that enables the high-strength alloy construction machinery parts piston to achieve the dual guarantees of structural stability and wear resistance under high temperature and high pressure environments, ensuring the continuous and efficient operation of construction machinery engines.