How does the bottom of the tank of construction machinery parts directly affect the service life of the whole machine?

Release Time : 2025-06-05

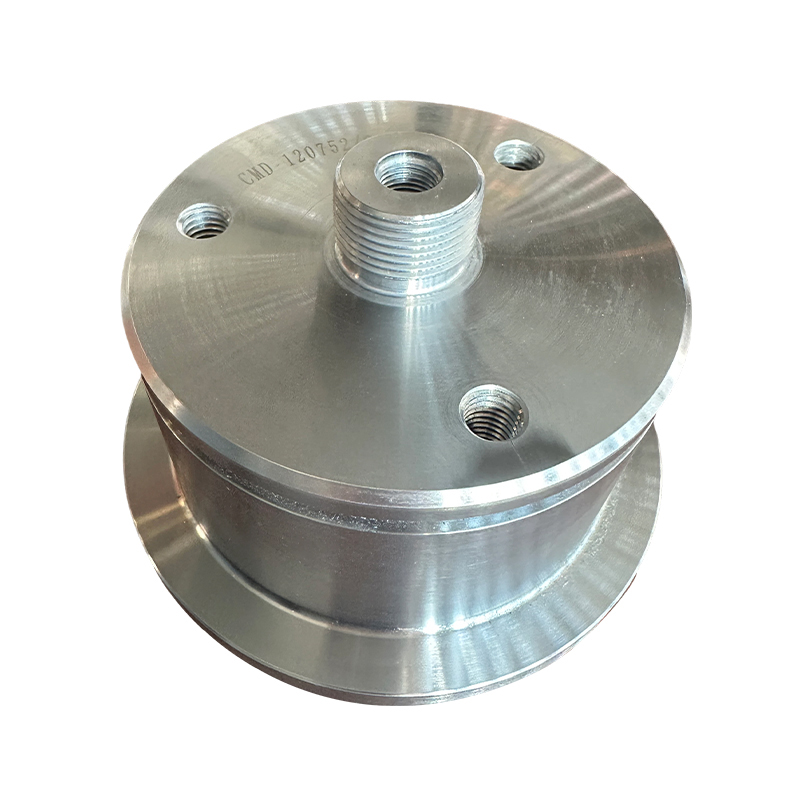

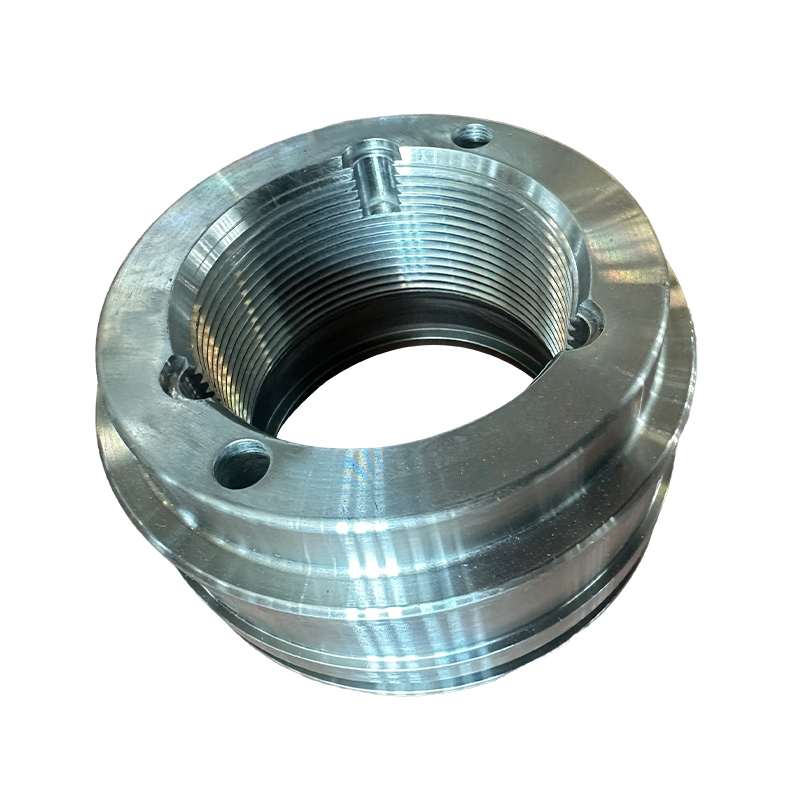

In the construction machinery system, the hydraulic cylinder is one of the core components for realizing the power output and execution of the equipment. As a key component of the hydraulic cylinder, the performance and quality of the bottom of the tank play a decisive role in the stability, safety and life of the whole machine. The bottom of the tank is not only the pressure-bearing end in the hydraulic cylinder structure, but also an important support point of the sealing system. It directly bears the pressure from the hydraulic oil and the impact of the external load. Once fatigue, cracks or deformation occur, it will trigger a series of chain reactions, seriously affecting the service life of the whole machine.

1. The basic functions and importance of the bottom of the tank

The bottom of the tank is usually located at one end of the hydraulic cylinder, and it undertakes the key tasks of closing the high-pressure chamber, connecting other structural parts and bearing complex loads. During the operation of the hydraulic system, the bottom of the tank must not only resist the axial force generated by the hydraulic pressure, but also withstand the additional stress caused by vibration, impact and temperature changes. Therefore, its design strength, material selection and manufacturing process must meet high reliability requirements.

In practical applications, if the bottom of the tank cannot effectively resist these complex mechanical environments, it may lead to failures such as seal failure, internal leakage, structural deformation and even fracture. These problems not only affect the normal operation of the hydraulic cylinder, but also lead to a decrease in the efficiency of the entire mechanical equipment, increase the maintenance frequency, and shorten the overall service life.

2. Material selection determines the basic performance of the bottom of the tank

In order to cope with high-intensity working conditions, the bottom of the tank is usually made of high-strength metal materials such as high-quality carbon steel, alloy steel or stainless steel. These materials have good tensile strength, wear resistance and fatigue resistance, and can operate stably under high-pressure environments for a long time.

In addition, with the development of technology, some high-end engineering machinery manufacturers have begun to use heat treatment processes (such as quenching and tempering) to improve the surface hardness and corrosion resistance of the bottom of the tank, further extending its service life. At the same time, some products have also introduced advanced coating technology to enhance their adaptability in harsh environments such as moisture and dust.

3. Structural design affects load-bearing capacity and fatigue life

The structural design of the bottom of the tank has a direct impact on its load-bearing capacity and fatigue life. For example, in terms of shape design, reasonable transition fillets can effectively reduce stress concentration and avoid early cracking due to excessive local stress; in terms of connection methods, when using threaded connection, flange connection or welding, it is also necessary to optimize according to the use conditions to ensure that the connection is firm and not easy to loosen.

In addition, finite element analysis (FEA) technology is increasingly used in modern design to simulate and calculate the stress conditions of the bottom of the tank under different working conditions, thereby achieving structural optimization. This data-driven design method not only improves the reliability of the bottom of the tank, but also provides a guarantee for the long-life operation of the whole machine.

4. Manufacturing process determines the final quality

Even if you have excellent materials and designs, the quality of the bottom of the tank is still difficult to guarantee if the manufacturing process is not up to standard. At present, common manufacturing processes include forging, casting, CNC machining, etc. Among them, the forging process is the first choice for high-end bottom of the tank manufacturing because of its dense organization and grain refinement, which can significantly improve the strength and toughness of the material.

After the processing is completed, strict inspection processes are required, such as non-destructive testing, dimensional accuracy measurement, pressure testing, etc., to ensure that each bottom of the tank meets the quality standards. Only products that have been strictly controlled can truly provide strong support for the stable operation of the whole machine.

5. The specific impact of the bottom of the tank problem on the life of the whole machine

When there is a quality problem with the bottom of the tank, it may bring the following negative effects:

Seal failure: deformation or wear of the bottom of the tank will cause the seal ring to not fit tightly, causing hydraulic oil leakage and reducing system efficiency.

Structural fatigue: The bottom of the tank that is in a high stress state for a long time is prone to microcracks, which gradually expand and may eventually cause a fracture accident.

System instability: Since the bottom of the tank is the end pressure-bearing component of the hydraulic system, its damage will directly lead to unstable action and slow response of the hydraulic cylinder, affecting the operating performance of the whole machine.

Frequent maintenance: When there is a problem with the bottom of the tank, it is often necessary to shut down for inspection or even replace the entire hydraulic cylinder, which increases maintenance costs and reduces equipment utilization.

In the field of engineering machinery, the saying "details determine success or failure" is particularly applicable. Although the bottom of the tank is only a component of the hydraulic cylinder, its performance is directly related to the operating stability and service life of the entire equipment. A high-quality bottom of the tank can not only improve the working efficiency of the equipment, but also greatly reduce the frequency of later maintenance and reduce the overall operating costs.

Therefore, in the design and manufacturing process of the hydraulic system, enterprises should attach great importance to the material selection, design and process control of the bottom of the tank, and create more reliable and durable core components of engineering equipment through technological innovation and quality management. Only in this way can we truly achieve the product goal of "high performance and long life" and meet the increasingly stringent needs of industrial application scenarios.

1. The basic functions and importance of the bottom of the tank

The bottom of the tank is usually located at one end of the hydraulic cylinder, and it undertakes the key tasks of closing the high-pressure chamber, connecting other structural parts and bearing complex loads. During the operation of the hydraulic system, the bottom of the tank must not only resist the axial force generated by the hydraulic pressure, but also withstand the additional stress caused by vibration, impact and temperature changes. Therefore, its design strength, material selection and manufacturing process must meet high reliability requirements.

In practical applications, if the bottom of the tank cannot effectively resist these complex mechanical environments, it may lead to failures such as seal failure, internal leakage, structural deformation and even fracture. These problems not only affect the normal operation of the hydraulic cylinder, but also lead to a decrease in the efficiency of the entire mechanical equipment, increase the maintenance frequency, and shorten the overall service life.

2. Material selection determines the basic performance of the bottom of the tank

In order to cope with high-intensity working conditions, the bottom of the tank is usually made of high-strength metal materials such as high-quality carbon steel, alloy steel or stainless steel. These materials have good tensile strength, wear resistance and fatigue resistance, and can operate stably under high-pressure environments for a long time.

In addition, with the development of technology, some high-end engineering machinery manufacturers have begun to use heat treatment processes (such as quenching and tempering) to improve the surface hardness and corrosion resistance of the bottom of the tank, further extending its service life. At the same time, some products have also introduced advanced coating technology to enhance their adaptability in harsh environments such as moisture and dust.

3. Structural design affects load-bearing capacity and fatigue life

The structural design of the bottom of the tank has a direct impact on its load-bearing capacity and fatigue life. For example, in terms of shape design, reasonable transition fillets can effectively reduce stress concentration and avoid early cracking due to excessive local stress; in terms of connection methods, when using threaded connection, flange connection or welding, it is also necessary to optimize according to the use conditions to ensure that the connection is firm and not easy to loosen.

In addition, finite element analysis (FEA) technology is increasingly used in modern design to simulate and calculate the stress conditions of the bottom of the tank under different working conditions, thereby achieving structural optimization. This data-driven design method not only improves the reliability of the bottom of the tank, but also provides a guarantee for the long-life operation of the whole machine.

4. Manufacturing process determines the final quality

Even if you have excellent materials and designs, the quality of the bottom of the tank is still difficult to guarantee if the manufacturing process is not up to standard. At present, common manufacturing processes include forging, casting, CNC machining, etc. Among them, the forging process is the first choice for high-end bottom of the tank manufacturing because of its dense organization and grain refinement, which can significantly improve the strength and toughness of the material.

After the processing is completed, strict inspection processes are required, such as non-destructive testing, dimensional accuracy measurement, pressure testing, etc., to ensure that each bottom of the tank meets the quality standards. Only products that have been strictly controlled can truly provide strong support for the stable operation of the whole machine.

5. The specific impact of the bottom of the tank problem on the life of the whole machine

When there is a quality problem with the bottom of the tank, it may bring the following negative effects:

Seal failure: deformation or wear of the bottom of the tank will cause the seal ring to not fit tightly, causing hydraulic oil leakage and reducing system efficiency.

Structural fatigue: The bottom of the tank that is in a high stress state for a long time is prone to microcracks, which gradually expand and may eventually cause a fracture accident.

System instability: Since the bottom of the tank is the end pressure-bearing component of the hydraulic system, its damage will directly lead to unstable action and slow response of the hydraulic cylinder, affecting the operating performance of the whole machine.

Frequent maintenance: When there is a problem with the bottom of the tank, it is often necessary to shut down for inspection or even replace the entire hydraulic cylinder, which increases maintenance costs and reduces equipment utilization.

In the field of engineering machinery, the saying "details determine success or failure" is particularly applicable. Although the bottom of the tank is only a component of the hydraulic cylinder, its performance is directly related to the operating stability and service life of the entire equipment. A high-quality bottom of the tank can not only improve the working efficiency of the equipment, but also greatly reduce the frequency of later maintenance and reduce the overall operating costs.

Therefore, in the design and manufacturing process of the hydraulic system, enterprises should attach great importance to the material selection, design and process control of the bottom of the tank, and create more reliable and durable core components of engineering equipment through technological innovation and quality management. Only in this way can we truly achieve the product goal of "high performance and long life" and meet the increasingly stringent needs of industrial application scenarios.