How to use high-quality guide bushings to extend the service life of construction machinery?

Release Time : 2025-06-18

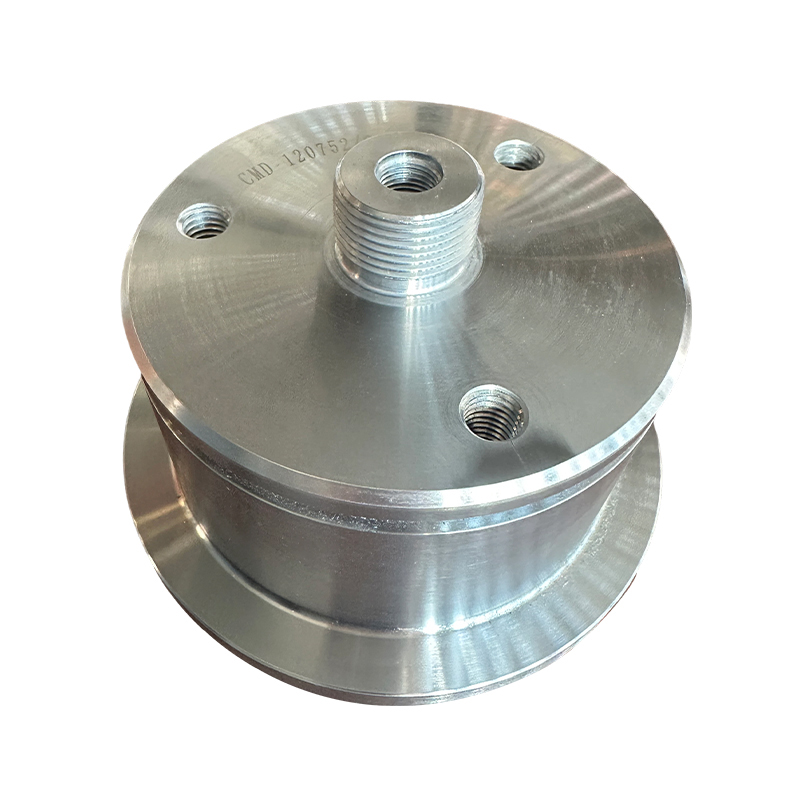

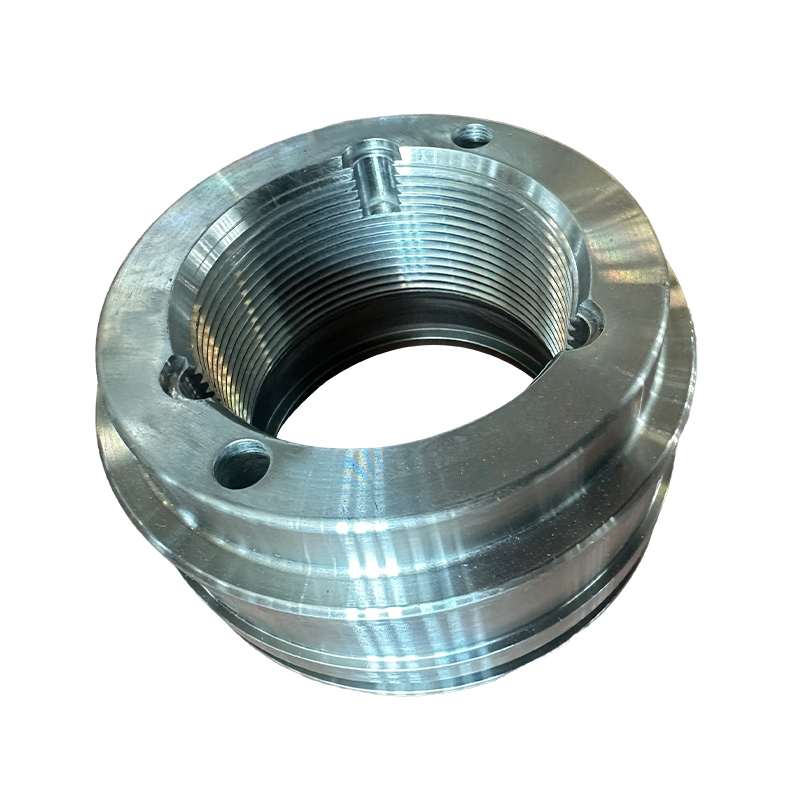

During the operation of construction machinery, the wear and aging of parts are important factors affecting the service life of equipment. As one of the key transmission and guide components, the quality of guide bushings is directly related to the stability, precision and durability of the whole machine. High-quality guide bushings can not only effectively reduce the internal friction and loss of the machinery, but also maintain structural stability under complex working conditions, thereby significantly extending the overall service life of the construction machinery.

High-quality guide bushings are usually made of high-quality materials and undergo precision machining and heat treatment processes to give them good wear resistance, pressure resistance and dimensional stability. These characteristics enable guide bushings to maintain their original geometric shape and fit accuracy during long-term use, avoiding the problem of excessive fit clearance caused by deformation or wear. This stable fit state is crucial for the normal operation of mechanical equipment. It can effectively prevent additional vibration and stress concentration caused by motion deviation, thereby reducing the loss rate of other related components.

In practical applications, guide bushings mainly play the role of support, guidance and positioning, and are widely used in hydraulic cylinders, connecting rod mechanisms, sliding components and other parts. When the quality of guide bushing is poor, it is easy to get stuck, deflect or even break, which will not only affect the operating efficiency of the equipment, but also cause chain damage to surrounding parts. High-quality guide bushings, with their excellent surface finish and reasonable tolerance control, can ensure smoother cooperation between moving parts, reduce unnecessary energy loss and heat accumulation, and further improve the operating efficiency and safety of the overall system.

In addition, high-quality guide bushings also show stronger adaptability when facing harsh working environments. For example, in high-dust, high-temperature or humid environments, ordinary guide bushings may be damaged prematurely due to material aging or lubrication failure. High-quality guide bushings, by selecting materials with excellent corrosion resistance and self-lubricating properties, combined with surface coating treatment technology, effectively resist the influence of the external environment and maintain long-term stable operation. This superior environmental adaptability enables guide bushings to play their due role even under extreme conditions, providing continuous and reliable support for equipment.

It is worth mentioning that high-quality guide bushings also have good maintainability. Many advanced guide bushing designs take into account the convenience of later replacement and maintenance, and adopt modular structures or standardized interfaces, so that users can complete replacement without disassembling the entire system during daily maintenance. This design not only saves maintenance time, but also reduces maintenance costs, which helps enterprises to better manage equipment and extend the service life of equipment.

Overall, the application of high-quality guide bushings is not only an upgrade of individual components, but also a comprehensive improvement of the operating quality of the entire mechanical equipment. It reduces unplanned downtime and improves work efficiency through precise control and efficient protection of key moving parts, while also invisibly reducing the comprehensive operating costs of equipment. Especially in the context of frequent operation and high-intensity use of large-scale construction machinery, the selection of guide bushings with excellent performance has become a key link in ensuring equipment reliability and extending service life.

Therefore, whether from the perspective of improving equipment operation stability and reducing maintenance frequency, or from the perspective of optimizing resource allocation and improving economic benefits, the use of high-quality guide bushings is an effective strategy. With the continuous advancement of manufacturing technology and the increasingly stringent industry standards, the design and manufacturing of guide bushings in the future will pay more attention to material innovation and structural optimization, providing a more solid guarantee for the long life and high-performance operation of construction machinery.

High-quality guide bushings are usually made of high-quality materials and undergo precision machining and heat treatment processes to give them good wear resistance, pressure resistance and dimensional stability. These characteristics enable guide bushings to maintain their original geometric shape and fit accuracy during long-term use, avoiding the problem of excessive fit clearance caused by deformation or wear. This stable fit state is crucial for the normal operation of mechanical equipment. It can effectively prevent additional vibration and stress concentration caused by motion deviation, thereby reducing the loss rate of other related components.

In practical applications, guide bushings mainly play the role of support, guidance and positioning, and are widely used in hydraulic cylinders, connecting rod mechanisms, sliding components and other parts. When the quality of guide bushing is poor, it is easy to get stuck, deflect or even break, which will not only affect the operating efficiency of the equipment, but also cause chain damage to surrounding parts. High-quality guide bushings, with their excellent surface finish and reasonable tolerance control, can ensure smoother cooperation between moving parts, reduce unnecessary energy loss and heat accumulation, and further improve the operating efficiency and safety of the overall system.

In addition, high-quality guide bushings also show stronger adaptability when facing harsh working environments. For example, in high-dust, high-temperature or humid environments, ordinary guide bushings may be damaged prematurely due to material aging or lubrication failure. High-quality guide bushings, by selecting materials with excellent corrosion resistance and self-lubricating properties, combined with surface coating treatment technology, effectively resist the influence of the external environment and maintain long-term stable operation. This superior environmental adaptability enables guide bushings to play their due role even under extreme conditions, providing continuous and reliable support for equipment.

It is worth mentioning that high-quality guide bushings also have good maintainability. Many advanced guide bushing designs take into account the convenience of later replacement and maintenance, and adopt modular structures or standardized interfaces, so that users can complete replacement without disassembling the entire system during daily maintenance. This design not only saves maintenance time, but also reduces maintenance costs, which helps enterprises to better manage equipment and extend the service life of equipment.

Overall, the application of high-quality guide bushings is not only an upgrade of individual components, but also a comprehensive improvement of the operating quality of the entire mechanical equipment. It reduces unplanned downtime and improves work efficiency through precise control and efficient protection of key moving parts, while also invisibly reducing the comprehensive operating costs of equipment. Especially in the context of frequent operation and high-intensity use of large-scale construction machinery, the selection of guide bushings with excellent performance has become a key link in ensuring equipment reliability and extending service life.

Therefore, whether from the perspective of improving equipment operation stability and reducing maintenance frequency, or from the perspective of optimizing resource allocation and improving economic benefits, the use of high-quality guide bushings is an effective strategy. With the continuous advancement of manufacturing technology and the increasingly stringent industry standards, the design and manufacturing of guide bushings in the future will pay more attention to material innovation and structural optimization, providing a more solid guarantee for the long life and high-performance operation of construction machinery.