Pistons in Construction Machinery: Precision Guardians of the Power Core

Release Time : 2025-10-09

As the core moving component of construction machinery, such as internal combustion engines, hydraulic systems, and compressors, pistons' performance directly determines the efficiency, reliability, and service life of these equipment. From automotive engines to industrial compressors, from aircraft propulsion to ship propulsion, pistons continuously perform energy conversion and sealing functions under extreme operating conditions, becoming the indispensable "power heart" of modern mechanical engineering.

I. The Piston's Core Function: Energy Conversion and Sealing Barrier

1. Core Carrier of Power Conversion

In an internal combustion engine, the piston converts the thermal energy generated by fuel combustion into mechanical energy through reciprocating linear motion. For example, in a four-stroke engine, the piston draws in the fuel mixture during the intake stroke, increases pressure during the compression stroke, withstands the explosive force of the combustion gases during the power stroke to rotate the crankshaft, and removes exhaust gases during the exhaust stroke. Throughout this cycle, the piston's top is directly subjected to pressures up to 15 MPa and transient temperatures exceeding 2000°C, making its structural strength and thermal stability crucial.

2. Dynamic Sealing: A Key Line of Defense

The piston seals the cylinder with the piston ring assembly, preventing high-pressure gas from leaking into the crankcase and oil from entering the combustion chamber. The piston rings, with a trapezoidal cross-section, leverage their elasticity to form three sealing lines against the cylinder wall. The oil rings, with their scraping edges, control the oil film thickness, ensuring a balanced lubrication and sealing. Experimental data from a certain diesel engine's piston rings show that a failure of the piston ring seal can result in a 30% drop in engine power and a 15% increase in fuel consumption.

II. Breakthroughs in Materials Technology: Adapting to Extreme Operating Conditions

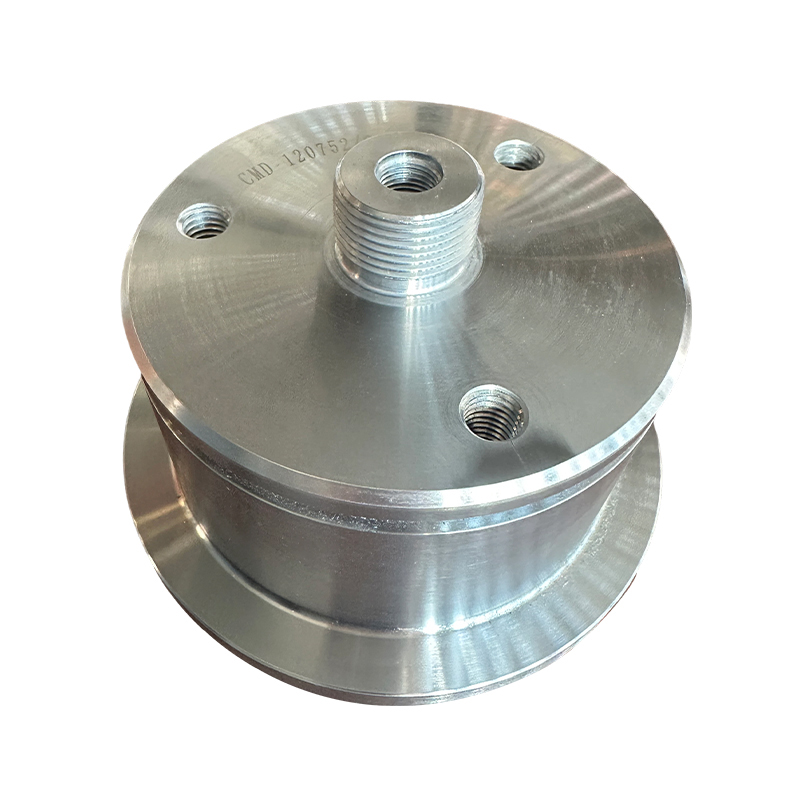

1. Aluminum Alloy Pistons: Balancing Lightweight and Thermal Conductivity

Modern engines widely use eutectic aluminum-silicon alloy pistons, which have a density only one-third that of cast iron and a thermal conductivity twice as high. For example, a certain diesel engine piston utilizes an aluminum-silicon alloy containing 12% copper. T6 heat treatment results in a hardness of HB120. Internal cooling channels reduce the piston top temperature by 50°C, effectively suppressing high-temperature creep. However, the linear expansion coefficient of aluminum alloy is twice that of cast iron, necessitating a negative clearance design to compensate for thermal deformation.

2. Cast Iron Pistons: Optimizing Wear Resistance and Cost

Ductile iron pistons, thanks to their spheroidized graphite structure, offer outstanding wear resistance. A certain type of engineering machinery piston uses ADI (Austempered Ductile Iron) material, boasting a tensile strength of 1000 MPa and an elongation of 8%. Under heavy loads, its service life is 40% longer than that of aluminum alloy pistons. At only 60% of the cost of steel pistons, it is widely used in medium- and low-speed, high-power engines.

3. Steel Pistons: The Ultimate Solution for High-Load Conditions

Steel pistons are the preferred choice for ultra-high-pressure applications, such as marine low-speed engines and large compressors. The piston head of a certain type of marine two-stroke engine is made of X40CrMoV5-1 hot-work die steel, achieving a hardness of HRC52 after vacuum quenching. Combined with nickel-based ceramic-coated piston rings, it can withstand burst pressures of 35 MPa. The composite steel piston connects the head and skirt with flexible bolts, ensuring strength while reducing thermal stress.

III. Evolution of Structural Design: From Single to Composite

1. Combustion Optimization of the Top Structure

Gasoline engine pistons generally adopt a flat or shallow concave top design to simplify the combustion chamber structure. Diesel engine pistons, on the other hand, use a deep concave top (ω-shaped) combined with the injector arrangement to create a tumble flow motion that improves mixing efficiency. The concave top depth of one direct injection engine piston reaches 8mm, increasing combustion speed by 20% and reducing particulate matter emissions by 40%.

2. Revolution in Wear Resistance in the Ring Band Area

The piston ring groove is the area most susceptible to wear. One piston utilizes laser cladding technology to deposit Stellite cobalt-based alloy onto the ring groove surface, achieving a hardness of HRC60 and improving wear resistance five times that of the base material. Furthermore, the land design has been changed from a traditional right angle to a rounded transition, reducing stress concentration by 30%.

3. Motion Control in the Skirt Design

The piston skirt utilizes an elliptical design (with the major axis perpendicular to the pin hole) and a tapered design (larger at the top and smaller at the bottom) to compensate for thermal deformation. The skirt of a certain type of piston utilizes a composite treatment of tin plating and graphite coating, which both reduces friction and prevents cylinder scuffing. In high-speed diesel engines, the application of a polyimide coating reduces skirt friction by 40% and extends its service life to 10,000 hours.

IV. Expansion of Application Areas: From Traditional to Emerging

1. The Automotive Industry's Demand for Lightweighting

With the advancement of the "Dual Carbon" strategy, automotive pistons are trending toward lower density and higher thermal conductivity. A hybrid engine piston utilizes a high-silicon aluminum alloy with a 22% silicon content, combined with 3D-printed cooling channels, reducing piston mass by 15% and improving thermal efficiency by 3%. Furthermore, smart pistons with integrated temperature sensors are beginning to be used in high-end vehicles, enabling real-time health monitoring.

2. Energy Efficiency Upgrades for Industrial Compressors

The annual production of fully enclosed piston compressors exceeds 300 million units, and their piston design directly impacts energy efficiency. The piston of a certain type of variable-frequency compressor utilizes an asymmetric ring groove design, combined with nano-coated piston rings, to increase volumetric efficiency by 8%, achieving a COP exceeding 3.0. In the cold chain logistics sector, ultra-low-temperature pistons (-80°C) have overcome the problem of low-temperature brittle fracture through special material formulations and surface treatment.

3. Cross-border Innovation in the New Energy Sector

Hydrogen fuel cell air compressors use oil-free pistons, achieved through self-lubrication using carbon fiber-reinforced PEEK material. A certain type of electric compressor piston integrates a piezoelectric ceramic sensor, enabling real-time cylinder pressure monitoring. Combined with AI algorithms to optimize control strategies, this improves system efficiency by 12%.

V. Future Trends: Intelligence and Sustainability

1. Breakthroughs in Materials Science

New materials such as self-healing ceramic coatings and amorphous alloys are entering the experimental stage. A nickel-based amorphous coating piston developed by a research institute exhibits only one-fifth the wear of traditional coatings under simulated operating conditions and exhibits self-healing cracks.

2. Innovation in Manufacturing Technology

Additive manufacturing technology enables the integrated molding of complex piston structures. A company's titanium alloy piston, manufactured using selective laser melting (SLM), is 50% lighter and features integrated cooling channels and sensor mounting points, shortening production cycles by 70%.

3. Digitalization and Predictive Maintenance

Smart pistons with integrated MEMS sensors can monitor parameters such as temperature, pressure, and vibration in real time, providing fault warnings through edge computing. A predictive maintenance system deployed by a mining equipment operator has reduced piston-related downtime by 65% and maintenance costs by 40%.

4. Advancing Green Manufacturing

Piston production is transitioning toward low-carbon production. One company, using recycled aluminum alloys and a closed-loop water-cooled casting process, has reduced carbon emissions per piston by 30%. Furthermore, the use of bio-based lubricants in piston assembly has reduced VOC emissions.

From the water pump piston invented by Ctesibius in ancient Greece to modern smart pistons with integrated sensors, this ancient component has consistently experienced breakthroughs in materials, structure, and function. As construction machinery evolves towards efficiency, intelligence, and green technologies, pistons, as core components of power conversion, are continuously pushing the boundaries of mechanical engineering through interdisciplinary technological innovation, providing inexhaustible support for the progress of human civilization.

I. The Piston's Core Function: Energy Conversion and Sealing Barrier

1. Core Carrier of Power Conversion

In an internal combustion engine, the piston converts the thermal energy generated by fuel combustion into mechanical energy through reciprocating linear motion. For example, in a four-stroke engine, the piston draws in the fuel mixture during the intake stroke, increases pressure during the compression stroke, withstands the explosive force of the combustion gases during the power stroke to rotate the crankshaft, and removes exhaust gases during the exhaust stroke. Throughout this cycle, the piston's top is directly subjected to pressures up to 15 MPa and transient temperatures exceeding 2000°C, making its structural strength and thermal stability crucial.

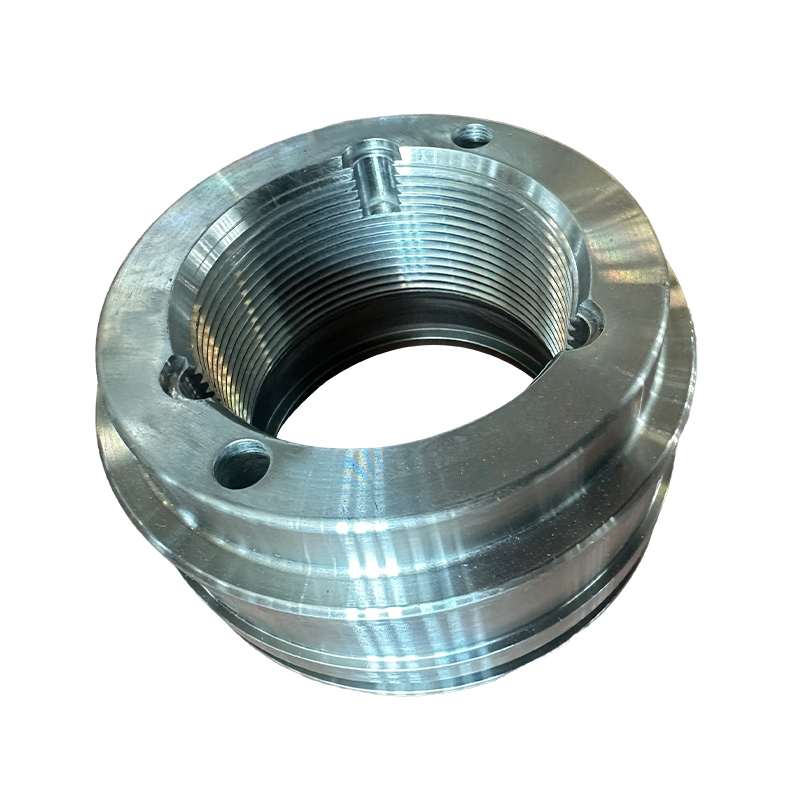

2. Dynamic Sealing: A Key Line of Defense

The piston seals the cylinder with the piston ring assembly, preventing high-pressure gas from leaking into the crankcase and oil from entering the combustion chamber. The piston rings, with a trapezoidal cross-section, leverage their elasticity to form three sealing lines against the cylinder wall. The oil rings, with their scraping edges, control the oil film thickness, ensuring a balanced lubrication and sealing. Experimental data from a certain diesel engine's piston rings show that a failure of the piston ring seal can result in a 30% drop in engine power and a 15% increase in fuel consumption.

II. Breakthroughs in Materials Technology: Adapting to Extreme Operating Conditions

1. Aluminum Alloy Pistons: Balancing Lightweight and Thermal Conductivity

Modern engines widely use eutectic aluminum-silicon alloy pistons, which have a density only one-third that of cast iron and a thermal conductivity twice as high. For example, a certain diesel engine piston utilizes an aluminum-silicon alloy containing 12% copper. T6 heat treatment results in a hardness of HB120. Internal cooling channels reduce the piston top temperature by 50°C, effectively suppressing high-temperature creep. However, the linear expansion coefficient of aluminum alloy is twice that of cast iron, necessitating a negative clearance design to compensate for thermal deformation.

2. Cast Iron Pistons: Optimizing Wear Resistance and Cost

Ductile iron pistons, thanks to their spheroidized graphite structure, offer outstanding wear resistance. A certain type of engineering machinery piston uses ADI (Austempered Ductile Iron) material, boasting a tensile strength of 1000 MPa and an elongation of 8%. Under heavy loads, its service life is 40% longer than that of aluminum alloy pistons. At only 60% of the cost of steel pistons, it is widely used in medium- and low-speed, high-power engines.

3. Steel Pistons: The Ultimate Solution for High-Load Conditions

Steel pistons are the preferred choice for ultra-high-pressure applications, such as marine low-speed engines and large compressors. The piston head of a certain type of marine two-stroke engine is made of X40CrMoV5-1 hot-work die steel, achieving a hardness of HRC52 after vacuum quenching. Combined with nickel-based ceramic-coated piston rings, it can withstand burst pressures of 35 MPa. The composite steel piston connects the head and skirt with flexible bolts, ensuring strength while reducing thermal stress.

III. Evolution of Structural Design: From Single to Composite

1. Combustion Optimization of the Top Structure

Gasoline engine pistons generally adopt a flat or shallow concave top design to simplify the combustion chamber structure. Diesel engine pistons, on the other hand, use a deep concave top (ω-shaped) combined with the injector arrangement to create a tumble flow motion that improves mixing efficiency. The concave top depth of one direct injection engine piston reaches 8mm, increasing combustion speed by 20% and reducing particulate matter emissions by 40%.

2. Revolution in Wear Resistance in the Ring Band Area

The piston ring groove is the area most susceptible to wear. One piston utilizes laser cladding technology to deposit Stellite cobalt-based alloy onto the ring groove surface, achieving a hardness of HRC60 and improving wear resistance five times that of the base material. Furthermore, the land design has been changed from a traditional right angle to a rounded transition, reducing stress concentration by 30%.

3. Motion Control in the Skirt Design

The piston skirt utilizes an elliptical design (with the major axis perpendicular to the pin hole) and a tapered design (larger at the top and smaller at the bottom) to compensate for thermal deformation. The skirt of a certain type of piston utilizes a composite treatment of tin plating and graphite coating, which both reduces friction and prevents cylinder scuffing. In high-speed diesel engines, the application of a polyimide coating reduces skirt friction by 40% and extends its service life to 10,000 hours.

IV. Expansion of Application Areas: From Traditional to Emerging

1. The Automotive Industry's Demand for Lightweighting

With the advancement of the "Dual Carbon" strategy, automotive pistons are trending toward lower density and higher thermal conductivity. A hybrid engine piston utilizes a high-silicon aluminum alloy with a 22% silicon content, combined with 3D-printed cooling channels, reducing piston mass by 15% and improving thermal efficiency by 3%. Furthermore, smart pistons with integrated temperature sensors are beginning to be used in high-end vehicles, enabling real-time health monitoring.

2. Energy Efficiency Upgrades for Industrial Compressors

The annual production of fully enclosed piston compressors exceeds 300 million units, and their piston design directly impacts energy efficiency. The piston of a certain type of variable-frequency compressor utilizes an asymmetric ring groove design, combined with nano-coated piston rings, to increase volumetric efficiency by 8%, achieving a COP exceeding 3.0. In the cold chain logistics sector, ultra-low-temperature pistons (-80°C) have overcome the problem of low-temperature brittle fracture through special material formulations and surface treatment.

3. Cross-border Innovation in the New Energy Sector

Hydrogen fuel cell air compressors use oil-free pistons, achieved through self-lubrication using carbon fiber-reinforced PEEK material. A certain type of electric compressor piston integrates a piezoelectric ceramic sensor, enabling real-time cylinder pressure monitoring. Combined with AI algorithms to optimize control strategies, this improves system efficiency by 12%.

V. Future Trends: Intelligence and Sustainability

1. Breakthroughs in Materials Science

New materials such as self-healing ceramic coatings and amorphous alloys are entering the experimental stage. A nickel-based amorphous coating piston developed by a research institute exhibits only one-fifth the wear of traditional coatings under simulated operating conditions and exhibits self-healing cracks.

2. Innovation in Manufacturing Technology

Additive manufacturing technology enables the integrated molding of complex piston structures. A company's titanium alloy piston, manufactured using selective laser melting (SLM), is 50% lighter and features integrated cooling channels and sensor mounting points, shortening production cycles by 70%.

3. Digitalization and Predictive Maintenance

Smart pistons with integrated MEMS sensors can monitor parameters such as temperature, pressure, and vibration in real time, providing fault warnings through edge computing. A predictive maintenance system deployed by a mining equipment operator has reduced piston-related downtime by 65% and maintenance costs by 40%.

4. Advancing Green Manufacturing

Piston production is transitioning toward low-carbon production. One company, using recycled aluminum alloys and a closed-loop water-cooled casting process, has reduced carbon emissions per piston by 30%. Furthermore, the use of bio-based lubricants in piston assembly has reduced VOC emissions.

From the water pump piston invented by Ctesibius in ancient Greece to modern smart pistons with integrated sensors, this ancient component has consistently experienced breakthroughs in materials, structure, and function. As construction machinery evolves towards efficiency, intelligence, and green technologies, pistons, as core components of power conversion, are continuously pushing the boundaries of mechanical engineering through interdisciplinary technological innovation, providing inexhaustible support for the progress of human civilization.