How to reduce the friction coefficient of construction machinery parts piston during operation?

Release Time : 2025-09-24

As a core moving component in an engine, the friction coefficient of a piston directly impacts mechanical efficiency, energy consumption, and service life. The friction pair formed by the piston and cylinder liner is one of the areas with the highest friction losses in the engine. Reducing the friction coefficient in this area requires a systematic solution encompassing multiple dimensions, including material selection, surface treatment, lubrication technology, structural design, and operational maintenance.

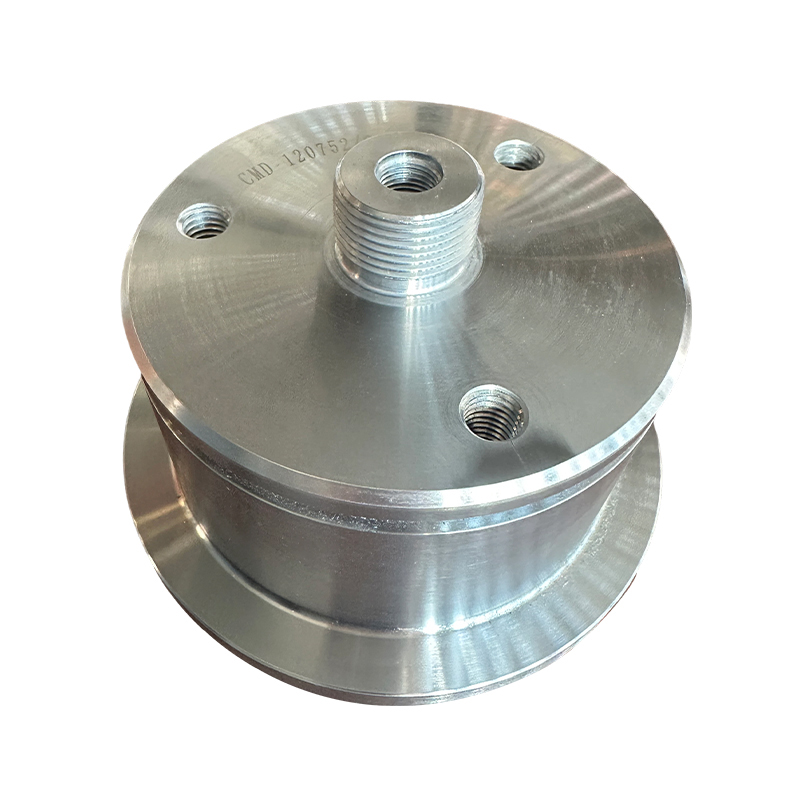

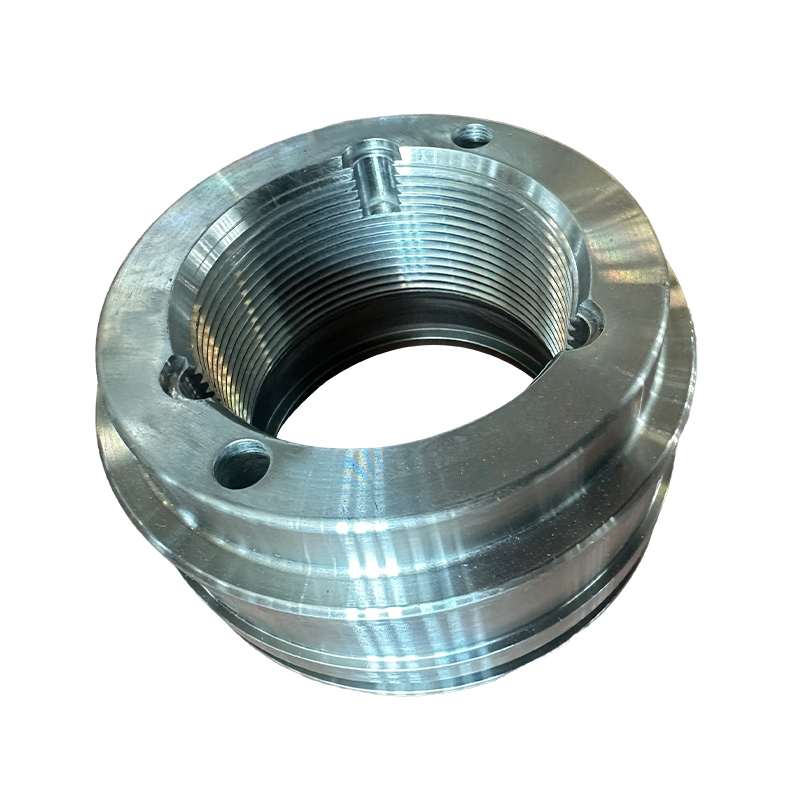

Material selection is fundamental to reducing friction in pistons. Modern pistons are often made of high-strength aluminum alloys or composite materials, which combine lightweight and wear resistance to reduce friction losses caused by inertia. For example, by adding elements such as silicon, copper, and magnesium, the strength of aluminum alloy pistons can be significantly increased while simultaneously reducing their density to levels approaching those of engineering plastics. This reduces piston mass and inertial forces during high-speed reciprocating motion, thereby reducing friction. Furthermore, as the piston ring directly contacts the cylinder liner, its material must be well-matched to the liner. Chrome-plated or composite-coated piston rings, for example, can significantly reduce the friction coefficient and extend service life.

Surface treatment technology is a key step in optimizing the friction performance of pistons in construction machinery parts. The piston skirt, as the primary friction zone, has a direct impact on its surface condition. Finishing processes such as honing and polishing can reduce surface roughness and minimize friction between microscopic protrusions and the cylinder liner. Laser microtexturing can also be used to create regularly spaced pits or grooves on the piston surface, which store lubricant and form a dynamic oil film, transforming dry friction into fluid lubrication and significantly reducing the friction coefficient. Furthermore, coating the piston skirt with solid lubricants such as graphite or molybdenum disulfide provides temporary lubrication during cold starts or lubrication starvation, preventing severe wear such as cylinder scuffing.

Optimizing the lubrication system is crucial for reducing piston friction in construction machinery parts. Engine lubricants must possess appropriate viscosity and extreme pressure and anti-wear properties to form a stable oil film during the high-speed reciprocating motion of the piston. Modern engines use oil nozzles to directly inject lubricant into the piston cavity, enhancing lubrication between the piston skirt and cylinder liner. Furthermore, using platform-grid honing technology on the cylinder liner surface creates microscopic grooves with high oil storage capacity, which continuously release lubricant during piston movement, improving boundary lubrication conditions. Furthermore, the trend toward low-viscosity lubricants requires optimizing additive formulations to balance oil film strength and frictional resistance, avoiding oil film breakdown and increased wear caused by excessively low viscosity.

Structural design improvements are a long-term approach to reducing friction in construction machinery parts pistons. Semi-drag pistons reduce the contact area of the friction pair by minimizing the skirt contact area; the barreled surface design of the piston rings enhances fit with the cylinder liner and promotes even distribution of lubricant. Furthermore, controlling the clearance between the piston and cylinder liner requires a balanced approach to lubrication and sealing: too small a clearance can easily lead to thermal expansion seizure, while too large a clearance increases impact friction. Modern engines use precision machining and thermal expansion compensation to maintain this clearance within a reasonable range, ensuring lubricant film formation while avoiding excessive friction losses.

Non-contact friction reduction technology offers new approaches for optimizing friction in construction machinery parts pistons. Although magnetic levitation or air cushion technology has not yet been widely used in the piston industry, their principles are worth learning from. For example, integrating a gas bearing within the piston cavity, using compressed air to create a non-contact support, can completely eliminate solid friction. Despite current limitations in cost and reliability, the potential for this technology's application in high-end engines or specialized operating conditions warrants attention.

Operational maintenance is essential for maintaining low friction in construction machinery pistons. Regularly replacing standard lubricants prevents oil film breakdown caused by oil aging; maintaining a properly functioning engine cooling system prevents gap changes caused by piston overheating and expansion; and avoiding prolonged low-speed, high-load operation reduces the proportion of boundary lubrication and friction coefficient fluctuations. Furthermore, driver habits, such as gentle starts and avoiding sudden acceleration, can indirectly reduce piston friction losses.

Reducing the friction coefficient of construction machinery pistons requires collaborative innovation in materials, processes, lubrication, structure, and maintenance. From high-strength aluminum alloys to laser microtexturing, from intelligent lubrication systems to contactless support technology, each technological breakthrough is pushing the limits of piston friction performance. In the future, with the integration of nanomaterials and digital twin technology, piston friction optimization will move towards a more precise and dynamic stage, providing core support for improving the energy efficiency and extending the life of construction machinery.