How to determine the interference fit between the ring gear and the shaft in engineering machinery?

Release Time : 2025-12-17

Determining the interference fit between ring gear and shaft in engineering machinery requires a comprehensive solution that considers multiple factors, including material properties, torque transmission requirements, assembly processes, and long-term stability. The core logic is to combine theoretical calculations with engineering practice to ensure that the interference fit meets functional requirements without causing failure risks due to design flaws.

From a material properties perspective, the elastic modulus and yield strength of the ring gear and shaft are fundamental parameters for interference fit design. For example, when both the gear and shaft are made of high-strength alloy steel, the material has strong elastic deformation capacity and can withstand a large interference fit without plastic deformation. If the material is softer, the upper limit of the interference fit must be strictly controlled to avoid assembly stress exceeding the material's allowable stress. Furthermore, differences in the thermal expansion coefficients of the materials also affect the selection of the interference fit. Under conditions of large temperature differences, compensation design is needed to offset the changes in interference fit caused by thermal expansion and contraction.

Torque transmission requirements are a key functional indicator for determining the interference fit. When the ring gear and shaft transmit power through an interference fit, the frictional force generated at the contact surface must be greater than the working torque. Theoretically, a larger interference fit results in greater contact pressure and increased friction; however, excessive interference fit can lead to assembly difficulties and even damage to mating surfaces. Therefore, the minimum interference fit must be calculated using the torque calculation formula, while also incorporating a safety factor to allow for design margins. For example, in heavy-duty transmission engineering machinery, the interference fit between the ring gear and shaft typically needs to be at least 1.5 times the peak torque to ensure reliability under dynamic loads.

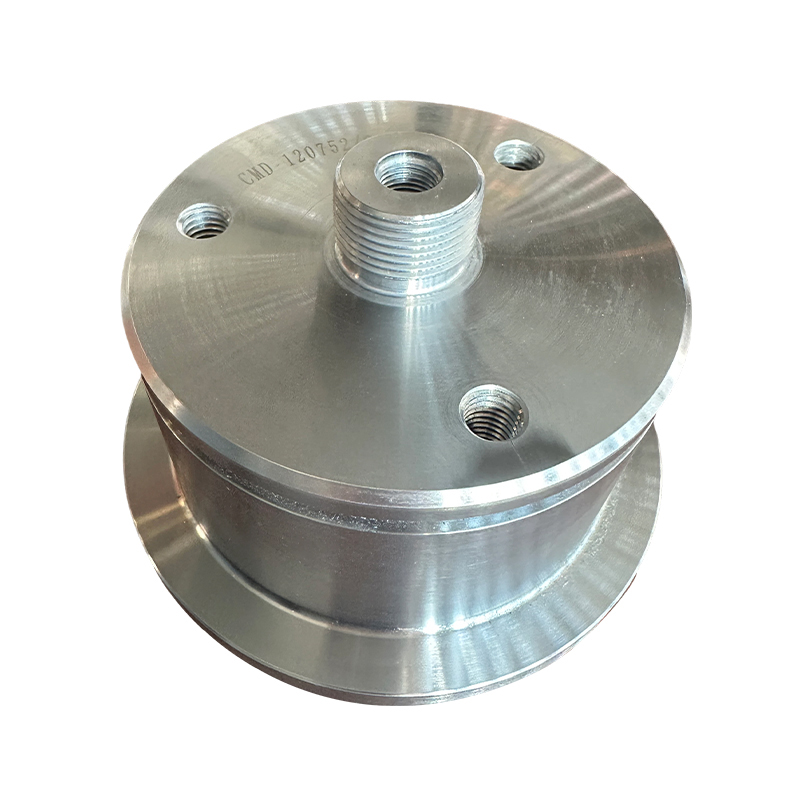

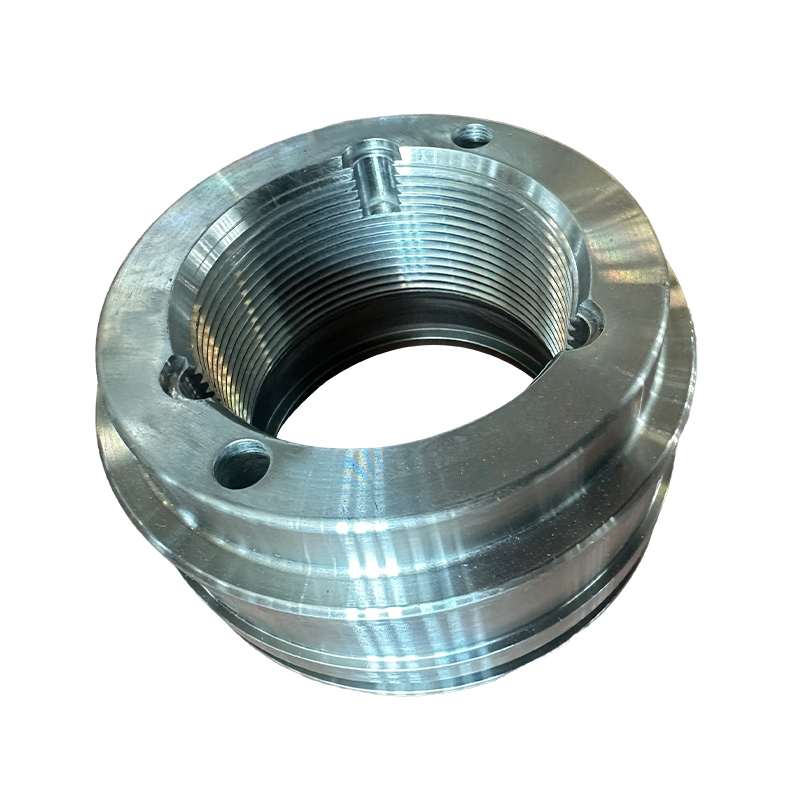

The assembly process directly constrains the selection of the interference fit. For medium to large-sized ring gears and shafts, a heat-fitting method is often used, increasing the dimensional difference by heating the gear or cooling the shaft to reduce assembly difficulty. During heat-fitting, the gear heating temperature must be controlled below the material tempering temperature to avoid affecting mechanical properties; the shaft cooling must prevent brittleness. In this case, the interference fit design must match the process parameters. For example, the actual interference fit during heat-fitting can be slightly smaller than the value during room temperature assembly to compensate for dimensional changes caused by thermal expansion. For precision transmission systems, special processes such as hydraulic assembly or cryogenic assembly can be used to further expand the applicable range of interference fits.

Long-term stability requires interference fit design to balance fatigue life and wear resistance. Under alternating loads, stress concentration easily occurs at the interference fit, leading to fatigue cracks. Optimizing the structural design, such as using gradual interference or localized reinforcement processes, can disperse stress concentration. Simultaneously, selecting a combination of materials with high surface hardness and good wear resistance can reduce interference decay caused by wear during long-term operation. For example, in the slewing bearing of excavators in construction machinery, the interference fit between the ring gear and the shaft is often improved through surface carburizing to enhance wear resistance and extend service life.

Surface quality has a significant impact on the actual effect of the interference fit. The roughness and roundness error of the mating surfaces will change the actual contact area, thus affecting the coefficient of friction. If the surface roughness is too large, the actual interference fit needs to be appropriately increased to compensate for the loss of contact area; if the roundness error exceeds the standard, the interference fit needs to be increased to ensure uniform contact and avoid excessive local stress. Therefore, the mating surfaces of the ring gear and the shaft must be precision machined before assembly, and geometric tolerances must be strictly controlled.

Safety factors and standard specifications are the ultimate guarantee for interference fit design. In the construction machinery industry, safety factors are typically determined by referencing international standards and considering actual working conditions. For example, for ring gear transmissions subjected to frequent dynamic loads, a safety factor of 2.0 or higher can be used; for applications primarily subjected to static loads, it can be appropriately reduced. Simultaneously, industry standards regarding interference tolerance zones must be followed to ensure that the actual interference after assembly falls within the design range.

The determination of the interference fit between ring gear and shaft in construction machinery parts requires a closed-loop design system based on material properties, guided by torque requirements, constrained by assembly processes, aimed at long-term stability, optimized for surface quality, and guaranteed by a safety factor. Through the synergy of theoretical calculations, process verification, and long-term monitoring, precise control of the interference fit can be achieved, providing crucial support for the reliable operation of construction machinery.