How does a high-precision guide bushing ensure the precise alignment and smooth operation of hydraulic cylinders or moving parts?

Release Time : 2025-12-30

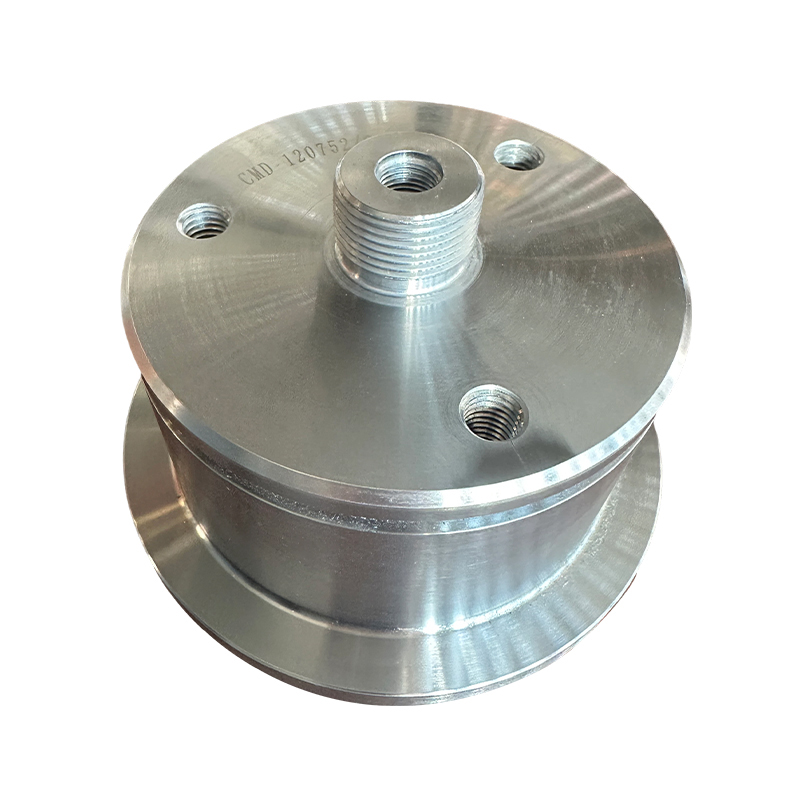

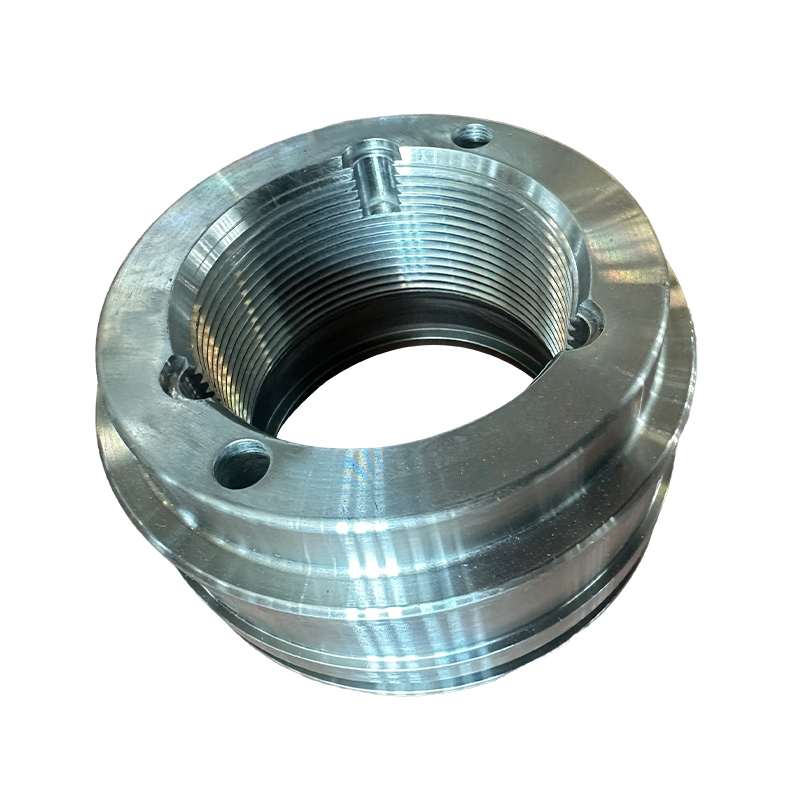

In the complex transmission and execution systems of engineering machinery, the stable operation of hydraulic cylinders, piston rods, and other reciprocating or rotating moving parts relies on a seemingly small but crucial component—the guide bushing. As a key interface for connection and support, the high-precision guide bushing not only bears the load but also determines the accuracy and smoothness of the motion trajectory at a microscopic level. Its sophisticated design and manufacturing process are the cornerstone for the efficient, reliable, and low-wear operation of the entire machine.

The core function of the guide bushing is "guidance" and "positioning." When the hydraulic cylinder extends or retracts, or the boom swings, the piston rod or connecting rod is affected by lateral forces, off-center loads, or vibrations. Without effective restraint, misalignment, jamming, or even direct metal-to-metal friction can easily occur, leading to seal damage, oil leakage, and even structural failure. A high-precision guide bushing, through strict tolerance control of its inner and outer diameters, precisely defines the axial position of the moving parts, ensuring that they always slide smoothly along the designed trajectory, avoiding unnecessary offset or wobbling. This precise alignment capability acts like an "invisible track" for moving parts, ensuring stability even under heavy loads, high frequencies, or impact conditions.

The key to achieving this performance lies in the geometric accuracy and surface quality of the bushing. High-quality guide bushings undergo precision machining and testing to ensure uniform clearance with the mating shaft, maintaining a perfect balance. This clearance must be neither too large (otherwise, the guiding function will be lost) nor too small (to avoid excessive frictional resistance or thermal expansion causing jamming). Simultaneously, the inner surface is typically treated with ultra-precision grinding or a special coating to achieve extremely high smoothness, significantly reducing the coefficient of friction. Some high-end products also employ self-lubricating materials or embedded solid lubricants, maintaining smooth operation with low friction and low wear even without external oil supply or under harsh lubrication conditions.

Material selection is equally crucial. High-precision guide bushings often use high-strength copper alloys, ductile iron, or special engineering composite materials. These materials not only possess excellent load-bearing and fatigue resistance but also maintain structural stability in muddy, dusty, or humid environments. Under certain operating conditions, the bushing surface is further coated or carburized to enhance wear resistance and corrosion resistance, preventing widening of clearances and guide failure caused by fretting wear or corrosion.

Furthermore, the installation fit of the guide bushing directly affects its performance. Its outer diameter must fit tightly but not with interference to the cylinder or support bore, ensuring no rotation or axial movement occurs during operation. Some designs also incorporate retaining grooves, locating pins, or elastic retaining rings to strengthen the fixing effect. This systematic approach to fit makes the bushing not just a component, but an indispensable functional unit in the entire moving pair.

From the perspective of the entire machine, the value of high-precision guide bushing far exceeds its physical dimensions. It reduces motion resistance, improves the response speed of the hydraulic system; reduces abnormal wear, extending the life of seals and piston rods; suppresses vibration and noise, improving operational comfort; and, more importantly, it fundamentally prevents cascading failures caused by guide failure, ensuring the continuous operation of equipment in harsh environments such as mines, construction sites, and ports.

In conclusion, high-precision guide bushings, though hidden within the machinery, safeguard the transmission of ton-level forces with millimeter-level precision. Their silent accuracy ensures dynamic reliability, representing an indispensable engineering wisdom behind the stable, accurate, and smooth operation of construction machinery. In modern equipment systems that prioritize efficiency and durability, a high-quality guide bushing is a silent promise of stability and trust.

The core function of the guide bushing is "guidance" and "positioning." When the hydraulic cylinder extends or retracts, or the boom swings, the piston rod or connecting rod is affected by lateral forces, off-center loads, or vibrations. Without effective restraint, misalignment, jamming, or even direct metal-to-metal friction can easily occur, leading to seal damage, oil leakage, and even structural failure. A high-precision guide bushing, through strict tolerance control of its inner and outer diameters, precisely defines the axial position of the moving parts, ensuring that they always slide smoothly along the designed trajectory, avoiding unnecessary offset or wobbling. This precise alignment capability acts like an "invisible track" for moving parts, ensuring stability even under heavy loads, high frequencies, or impact conditions.

The key to achieving this performance lies in the geometric accuracy and surface quality of the bushing. High-quality guide bushings undergo precision machining and testing to ensure uniform clearance with the mating shaft, maintaining a perfect balance. This clearance must be neither too large (otherwise, the guiding function will be lost) nor too small (to avoid excessive frictional resistance or thermal expansion causing jamming). Simultaneously, the inner surface is typically treated with ultra-precision grinding or a special coating to achieve extremely high smoothness, significantly reducing the coefficient of friction. Some high-end products also employ self-lubricating materials or embedded solid lubricants, maintaining smooth operation with low friction and low wear even without external oil supply or under harsh lubrication conditions.

Material selection is equally crucial. High-precision guide bushings often use high-strength copper alloys, ductile iron, or special engineering composite materials. These materials not only possess excellent load-bearing and fatigue resistance but also maintain structural stability in muddy, dusty, or humid environments. Under certain operating conditions, the bushing surface is further coated or carburized to enhance wear resistance and corrosion resistance, preventing widening of clearances and guide failure caused by fretting wear or corrosion.

Furthermore, the installation fit of the guide bushing directly affects its performance. Its outer diameter must fit tightly but not with interference to the cylinder or support bore, ensuring no rotation or axial movement occurs during operation. Some designs also incorporate retaining grooves, locating pins, or elastic retaining rings to strengthen the fixing effect. This systematic approach to fit makes the bushing not just a component, but an indispensable functional unit in the entire moving pair.

From the perspective of the entire machine, the value of high-precision guide bushing far exceeds its physical dimensions. It reduces motion resistance, improves the response speed of the hydraulic system; reduces abnormal wear, extending the life of seals and piston rods; suppresses vibration and noise, improving operational comfort; and, more importantly, it fundamentally prevents cascading failures caused by guide failure, ensuring the continuous operation of equipment in harsh environments such as mines, construction sites, and ports.

In conclusion, high-precision guide bushings, though hidden within the machinery, safeguard the transmission of ton-level forces with millimeter-level precision. Their silent accuracy ensures dynamic reliability, representing an indispensable engineering wisdom behind the stable, accurate, and smooth operation of construction machinery. In modern equipment systems that prioritize efficiency and durability, a high-quality guide bushing is a silent promise of stability and trust.