What are the advantages of large flanges compared to other connection methods?

Release Time : 2025-07-30

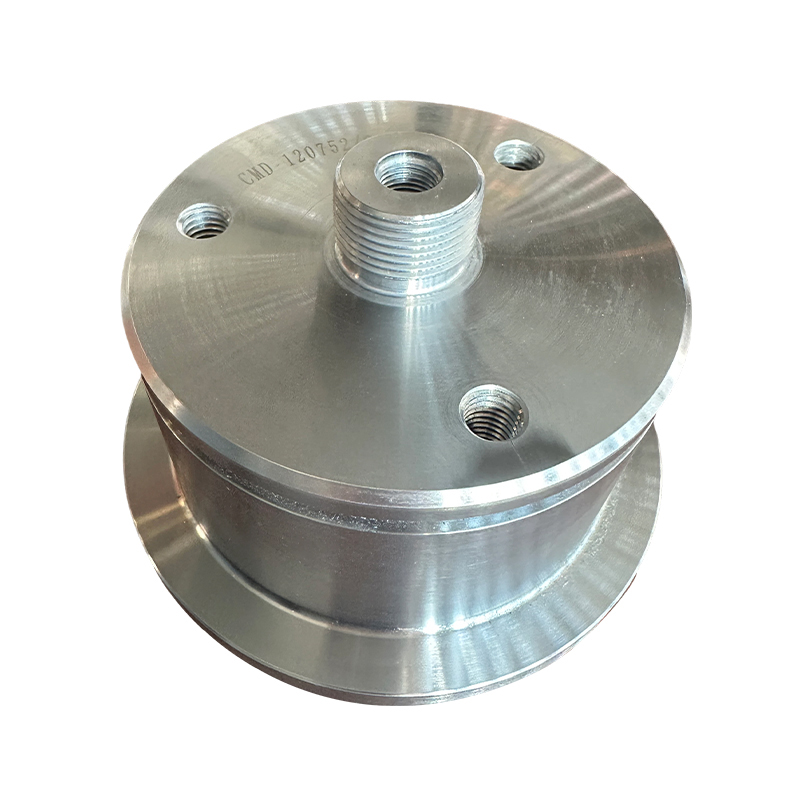

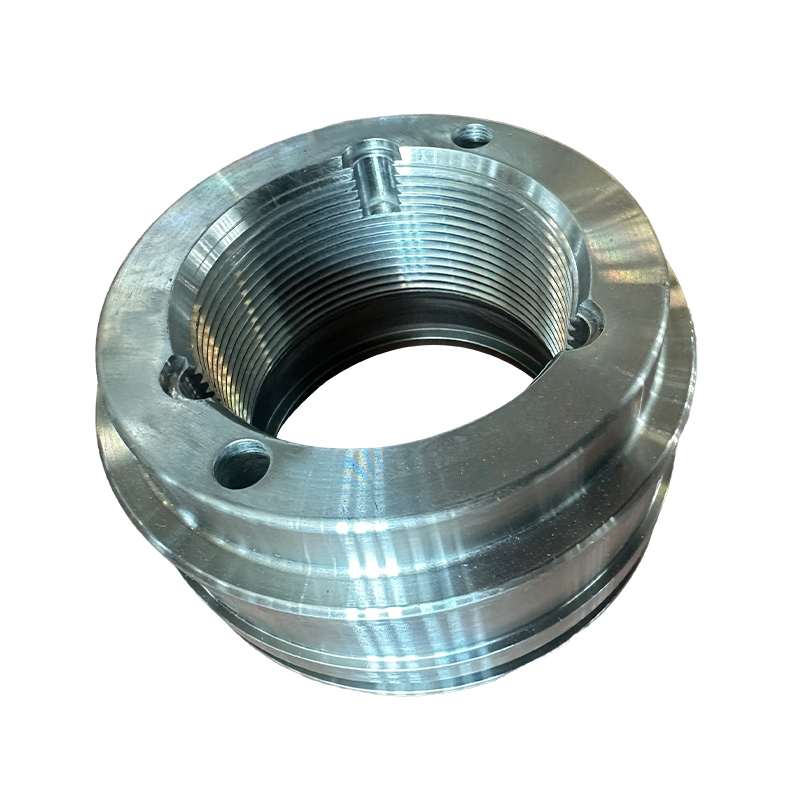

As an important connection method, large flanges occupy a key position in construction machinery components. Compared to other connection methods, large flanges excel in various industrial applications due to their unique advantages. From structural stability to ease of maintenance, large flanges demonstrate superior performance in multiple aspects, making them the preferred choice in numerous construction projects.

First, large flanges offer extremely high structural stability and reliability. Their design relies on two flanges tightly connected by bolts, making them robust in harsh operating environments such as high pressure, high temperature, and high vibration. Compared to other connection methods such as welding or compression fittings, large flanges can withstand greater mechanical and thermal stresses and are less susceptible to deformation or fracture. This characteristic of large flanges is particularly important in large machinery and piping systems, ensuring safe operation of the entire system and reducing the risk of failure due to connection failure.

Second, large flanges offer excellent sealing properties. Flange joints are typically sealed with gaskets, which not only effectively prevents leaks but also adapts to varying pressure and temperature conditions. Compared to welded connections, large flanges achieve a seal without compromising the integrity of the material, thus avoiding potential defects such as porosity and cracks that can occur during welding. Furthermore, when replacement or repair is needed, flanges can be removed by simply loosening the bolts, eliminating the need for re-cutting and reprocessing the joints as with welding. This significantly simplifies the process and reduces downtime.

Furthermore, large flanges are relatively easy to install and remove. Whether for new projects or upgrades to existing equipment, large flanges offer significant convenience. Their modular design allows for quick and easy on-site assembly, making them particularly suitable for locations with limited space or difficult access. In contrast, welded connections often require specialized technicians, complex equipment, and environmental requirements, which undoubtedly increase construction complexity and costs. Large flanges, on the other hand, can be quickly installed or removed under any conditions, improving work efficiency and reducing the consumption of manpower and material resources.

Furthermore, large flanges offer excellent compatibility and flexibility. Large flanges of varying sizes and specifications can be used interchangeably to meet the needs of a variety of complex applications. For example, when connecting multiple pipe sections, selecting the right large flange allows for seamless connection without the need for custom parts. Large flanges can also be easily integrated into automated control systems, using sensors to monitor connection status and promptly identify potential problems and take corrective action. This high degree of flexibility and compatibility has made large flanges widely used in modern factories and large-scale construction projects.

Large flanges also excel in safety. Because they are non-permanent connections, any anomalies can be immediately inspected and repaired, preventing damage to welds from crippling the entire system. Furthermore, large flanges are designed to adhere to strict standards and specifications, ensuring the highest safety levels at every stage. For industries with stringent safety requirements, such as petrochemicals and aerospace, large flanges are undoubtedly an excellent choice.

Environmental considerations are also a key consideration when choosing a connection method. Compared to welding, which produces fumes and harmful gases, the installation process of large flanges produces virtually no pollution, further aligning with the principles of green manufacturing. Furthermore, technological advances and the use of new materials have improved large flanges' corrosion and aging resistance, extending their service life while reducing waste and contributing to sustainable development.

Finally, considering economics, while the initial investment of large flanges may be slightly higher than some traditional connection methods, their low maintenance, high durability, and long lifespan make them more cost-effective in the long term. Especially for critical, long-term equipment, choosing large flanges not only reduces failure rates and repair frequency, but also lowers operating costs, creating greater value for the business.

In summary, large flanges offer significant advantages over other connection methods in terms of structural stability, sealing performance, installation ease, compatibility and flexibility, safety, environmental friendliness, and affordability. They not only meet modern industry's demand for efficient and reliable connection solutions but also promote technological advancement and development in related industries. Whether in new construction or retrofitting of older equipment, large flanges play an irreplaceable role, becoming a crucial support for the normal operation of various mechanical equipment and piping systems. Each improvement is designed to provide a better user experience and demonstrates a deep understanding and respect for user needs. In the future, with the continuous emergence of new materials and technologies, large flanges are expected to demonstrate their unique value in even more areas, leading new trends in industry development.

First, large flanges offer extremely high structural stability and reliability. Their design relies on two flanges tightly connected by bolts, making them robust in harsh operating environments such as high pressure, high temperature, and high vibration. Compared to other connection methods such as welding or compression fittings, large flanges can withstand greater mechanical and thermal stresses and are less susceptible to deformation or fracture. This characteristic of large flanges is particularly important in large machinery and piping systems, ensuring safe operation of the entire system and reducing the risk of failure due to connection failure.

Second, large flanges offer excellent sealing properties. Flange joints are typically sealed with gaskets, which not only effectively prevents leaks but also adapts to varying pressure and temperature conditions. Compared to welded connections, large flanges achieve a seal without compromising the integrity of the material, thus avoiding potential defects such as porosity and cracks that can occur during welding. Furthermore, when replacement or repair is needed, flanges can be removed by simply loosening the bolts, eliminating the need for re-cutting and reprocessing the joints as with welding. This significantly simplifies the process and reduces downtime.

Furthermore, large flanges are relatively easy to install and remove. Whether for new projects or upgrades to existing equipment, large flanges offer significant convenience. Their modular design allows for quick and easy on-site assembly, making them particularly suitable for locations with limited space or difficult access. In contrast, welded connections often require specialized technicians, complex equipment, and environmental requirements, which undoubtedly increase construction complexity and costs. Large flanges, on the other hand, can be quickly installed or removed under any conditions, improving work efficiency and reducing the consumption of manpower and material resources.

Furthermore, large flanges offer excellent compatibility and flexibility. Large flanges of varying sizes and specifications can be used interchangeably to meet the needs of a variety of complex applications. For example, when connecting multiple pipe sections, selecting the right large flange allows for seamless connection without the need for custom parts. Large flanges can also be easily integrated into automated control systems, using sensors to monitor connection status and promptly identify potential problems and take corrective action. This high degree of flexibility and compatibility has made large flanges widely used in modern factories and large-scale construction projects.

Large flanges also excel in safety. Because they are non-permanent connections, any anomalies can be immediately inspected and repaired, preventing damage to welds from crippling the entire system. Furthermore, large flanges are designed to adhere to strict standards and specifications, ensuring the highest safety levels at every stage. For industries with stringent safety requirements, such as petrochemicals and aerospace, large flanges are undoubtedly an excellent choice.

Environmental considerations are also a key consideration when choosing a connection method. Compared to welding, which produces fumes and harmful gases, the installation process of large flanges produces virtually no pollution, further aligning with the principles of green manufacturing. Furthermore, technological advances and the use of new materials have improved large flanges' corrosion and aging resistance, extending their service life while reducing waste and contributing to sustainable development.

Finally, considering economics, while the initial investment of large flanges may be slightly higher than some traditional connection methods, their low maintenance, high durability, and long lifespan make them more cost-effective in the long term. Especially for critical, long-term equipment, choosing large flanges not only reduces failure rates and repair frequency, but also lowers operating costs, creating greater value for the business.

In summary, large flanges offer significant advantages over other connection methods in terms of structural stability, sealing performance, installation ease, compatibility and flexibility, safety, environmental friendliness, and affordability. They not only meet modern industry's demand for efficient and reliable connection solutions but also promote technological advancement and development in related industries. Whether in new construction or retrofitting of older equipment, large flanges play an irreplaceable role, becoming a crucial support for the normal operation of various mechanical equipment and piping systems. Each improvement is designed to provide a better user experience and demonstrates a deep understanding and respect for user needs. In the future, with the continuous emergence of new materials and technologies, large flanges are expected to demonstrate their unique value in even more areas, leading new trends in industry development.