What critical role does high-precision machining play in ensuring dimensional tolerances and assembly stability for guide bushings?

Release Time : 2025-08-14

In the vast and precise operating systems of construction machinery, guide bushings, though tiny components, fulfill crucial roles in guidance, support, and friction reduction. Like the "invisible guardian" of mechanical joints, they silently withstand the friction and impact caused by high-frequency reciprocating motion, ensuring the smooth operation of hydraulic cylinders, connecting rod mechanisms, and transmission systems. Modern guide bushings are no longer the crude castings of the past. Instead, they are high-tech components that integrate advanced materials science, precision manufacturing processes, and industrial aesthetics. Their exceptional strength, wear resistance, and quietness redefine the value proposition of core construction machinery components.

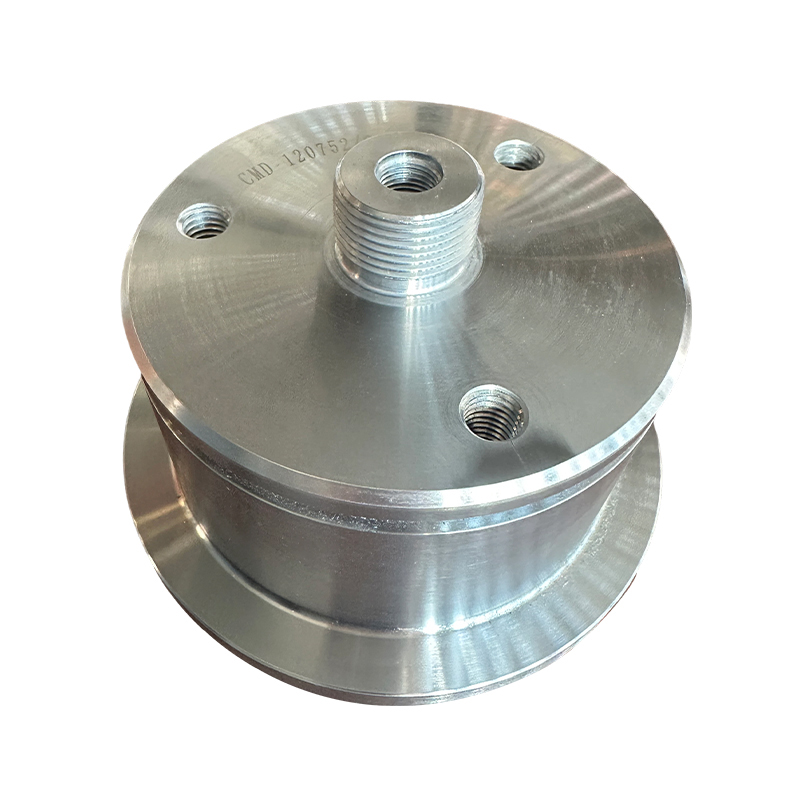

At first glance, the guide bushing's appearance reveals a refined aesthetic unlike any other. Through high-precision turning, grinding, and surface treatment, the guide bushing's exterior surfaces are as smooth as a mirror, with dimensional tolerances controlled to the micron level, burr-free end faces, and smooth, rounded corners. This extreme machining precision not only improves assembly efficiency but also reduces vibration and noise caused by excessive clearance. Often finished in dark gray, matte black, or a metallic finish, these guide bushings feature laser-engraved brand logos, making them both corrosion-resistant and recognizable, maintaining a clean and professional appearance amidst the complex internal structures of construction machinery. Though hidden deep within the equipment, their silent craftsmanship showcases the ingenuity of their makers.

Their core innovation lies in breakthroughs in both materials and structure. Traditional guide bushings are often constructed from cast iron or copper-based alloys, which are prone to wear and have a short lifespan. Modern, high-performance guide bushings, on the other hand, utilize composite materials, such as a sintered bond of a polytetrafluoroethylene (PTFE) liner with a high-strength steel backing, or integrally molded from self-lubricating powder metallurgy. These materials offer extremely low friction and excellent wear resistance, enabling long-term operation in dry-running or unstable oil film conditions without external lubrication, significantly reducing maintenance frequency. Some high-end models also incorporate built-in graphite or MoS₂ lubricating particles for "self-lubrication," maintaining stable performance even under extreme temperatures or heavy loads.

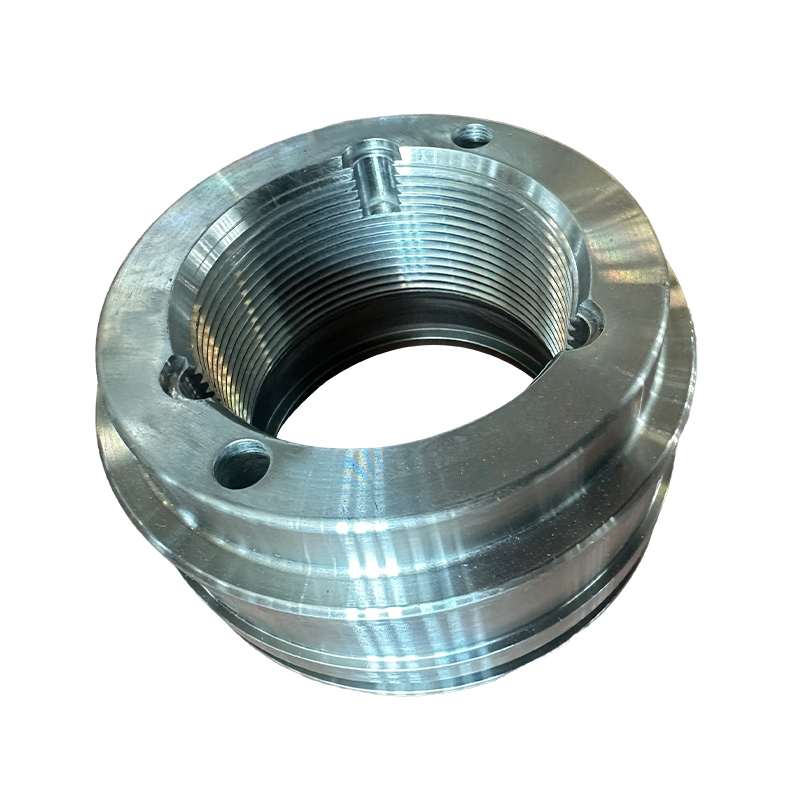

In terms of structural design, guide bushings also demonstrate an evolution towards intelligent technology. The optimized layout of internal oil grooves or reservoirs effectively stores lubricant and evenly distributes it across the friction surfaces. Chamfered edges and stress relief grooves prevent cracking caused by stress concentration. Some products utilize split-type or elastic preload structures for easier installation and to compensate for wear clearance, extending overall service life. These detailed innovations ensure that guide bushings maintain exceptional stability and reliability despite the harsh environments of construction machinery, such as frequent starts and stops, impact loads, and dust intrusion.

From a system integration perspective, the performance of guide bushings directly impacts overall machine efficiency and energy consumption. The low-friction design reduces power loss and improves hydraulic system response speed. High-precision guides ensure accurate actuator positioning and enhance operational precision. Vibration damping reduces overall noise and fatigue damage, extending equipment overhaul intervals. The use of high-quality guide bushings has become a key factor in enhancing product competitiveness in high-load equipment such as excavators, cranes, and concrete pump trucks.

Even more noteworthy is their sustainability. The long-life design reduces replacement frequency, spare parts consumption, and downtime losses. The use of recyclable metal materials aligns with green manufacturing trends. Some guide bushings also support remanufacturing processes, enabling recycling through surface repair and dimensional restoration, embracing the concept of a circular economy.

The guide bushing exemplifies the "small size, big power" of construction machinery. With silent tenacity, it carries tens of thousands of tons of force; with precision craftsmanship, it safeguards every precise movement. It is not only the fulcrum of mechanical movement but also the epitome of technological innovation and industrial aesthetics in the microcosm. In the pursuit of efficient, reliable, and intelligent modern engineering equipment, the guide bushing plays an irreplaceable role, supporting the progress of the entire industry.

At first glance, the guide bushing's appearance reveals a refined aesthetic unlike any other. Through high-precision turning, grinding, and surface treatment, the guide bushing's exterior surfaces are as smooth as a mirror, with dimensional tolerances controlled to the micron level, burr-free end faces, and smooth, rounded corners. This extreme machining precision not only improves assembly efficiency but also reduces vibration and noise caused by excessive clearance. Often finished in dark gray, matte black, or a metallic finish, these guide bushings feature laser-engraved brand logos, making them both corrosion-resistant and recognizable, maintaining a clean and professional appearance amidst the complex internal structures of construction machinery. Though hidden deep within the equipment, their silent craftsmanship showcases the ingenuity of their makers.

Their core innovation lies in breakthroughs in both materials and structure. Traditional guide bushings are often constructed from cast iron or copper-based alloys, which are prone to wear and have a short lifespan. Modern, high-performance guide bushings, on the other hand, utilize composite materials, such as a sintered bond of a polytetrafluoroethylene (PTFE) liner with a high-strength steel backing, or integrally molded from self-lubricating powder metallurgy. These materials offer extremely low friction and excellent wear resistance, enabling long-term operation in dry-running or unstable oil film conditions without external lubrication, significantly reducing maintenance frequency. Some high-end models also incorporate built-in graphite or MoS₂ lubricating particles for "self-lubrication," maintaining stable performance even under extreme temperatures or heavy loads.

In terms of structural design, guide bushings also demonstrate an evolution towards intelligent technology. The optimized layout of internal oil grooves or reservoirs effectively stores lubricant and evenly distributes it across the friction surfaces. Chamfered edges and stress relief grooves prevent cracking caused by stress concentration. Some products utilize split-type or elastic preload structures for easier installation and to compensate for wear clearance, extending overall service life. These detailed innovations ensure that guide bushings maintain exceptional stability and reliability despite the harsh environments of construction machinery, such as frequent starts and stops, impact loads, and dust intrusion.

From a system integration perspective, the performance of guide bushings directly impacts overall machine efficiency and energy consumption. The low-friction design reduces power loss and improves hydraulic system response speed. High-precision guides ensure accurate actuator positioning and enhance operational precision. Vibration damping reduces overall noise and fatigue damage, extending equipment overhaul intervals. The use of high-quality guide bushings has become a key factor in enhancing product competitiveness in high-load equipment such as excavators, cranes, and concrete pump trucks.

Even more noteworthy is their sustainability. The long-life design reduces replacement frequency, spare parts consumption, and downtime losses. The use of recyclable metal materials aligns with green manufacturing trends. Some guide bushings also support remanufacturing processes, enabling recycling through surface repair and dimensional restoration, embracing the concept of a circular economy.

The guide bushing exemplifies the "small size, big power" of construction machinery. With silent tenacity, it carries tens of thousands of tons of force; with precision craftsmanship, it safeguards every precise movement. It is not only the fulcrum of mechanical movement but also the epitome of technological innovation and industrial aesthetics in the microcosm. In the pursuit of efficient, reliable, and intelligent modern engineering equipment, the guide bushing plays an irreplaceable role, supporting the progress of the entire industry.