How is the clearance between the piston and cylinder liner set?

Release Time : 2025-08-27

Is both cold-start smoothness and hot-tightness balanced? The clearance between the piston and cylinder liner is a critical mechanical parameter in internal combustion engines or hydraulic systems, directly impacting power output, operating efficiency, component life, and overall reliability. This seemingly minute clearance is actually the synergy between thermodynamics, materials science, and precision manufacturing. If the clearance is too small, the piston, upon thermal expansion, may come into direct contact with the cylinder liner, leading to cylinder scuffing, seizure, or even engine failure. If the clearance is too large, knocking noise may occur during cold operation, exacerbating blowby and oil leakage during hot operation, reducing compression efficiency and accelerating oil degradation. Therefore, setting this clearance is essentially about finding a dynamic balance between cold-start smoothness and hot-tightness.

The piston experiences dramatic temperature fluctuations during operation. During a cold start, the metal components are at room temperature and their dimensions are minimal. Once the engine is running, the high temperatures generated in the combustion chamber are rapidly transferred to the piston top and diffused through the skirt, causing the piston material to expand. The cylinder liner also expands due to heat, but its thicker structure and longer heat conduction path generally lead to slower expansion rates and magnitudes than the piston. Therefore, when designing the clearance, it's crucial to anticipate the differences in deformation between the two under different operating conditions. This ensures a thin, stable lubricant film is consistently maintained between the piston and liner, whether during cold engine startup or full-load operation. This reduces friction and ensures effective sealing.

To achieve this, strategies to mitigate thermal expansion are incorporated into the piston's structural design. The piston skirt often features a non-circular profile, such as an elliptical or stepped shape. When cold, it assumes a specific geometric form, but upon heating, it gradually converges to a perfect circle, conforming to the cylindrical surface of the cylinder liner. Some pistons also incorporate internal constant-range steel plates or feature shaped pin holes to suppress lateral expansion and make hot dimensions more manageable. These structural features directly influence the clearance setting—it's not simply a matter of fitting a cylinder and a hole, but rather a precise matching of dynamic form and static space.

Lubricant plays multiple roles within the clearance. It not only acts as a lubricant but also provides heat dissipation and sealing. Appropriate clearance allows the oil to form a hydrodynamic film during the reciprocating motion of the piston, preventing direct metal-to-metal contact. Furthermore, in areas where the piston rings fail to fully seal, the oil film temporarily prevents high-temperature combustion gas from leaking downward or oil from leaking upward. If the clearance is too large, the oil film can be easily breached by high-pressure gas, leading to blowby. If the clearance is too small, the oil film is difficult to establish, lubrication fails, and friction increases dramatically.

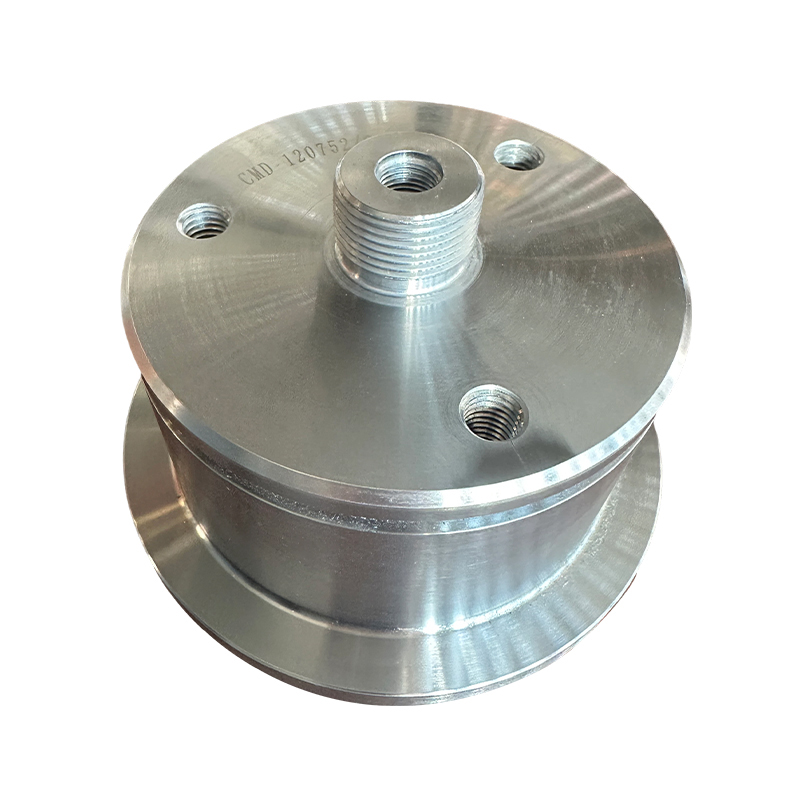

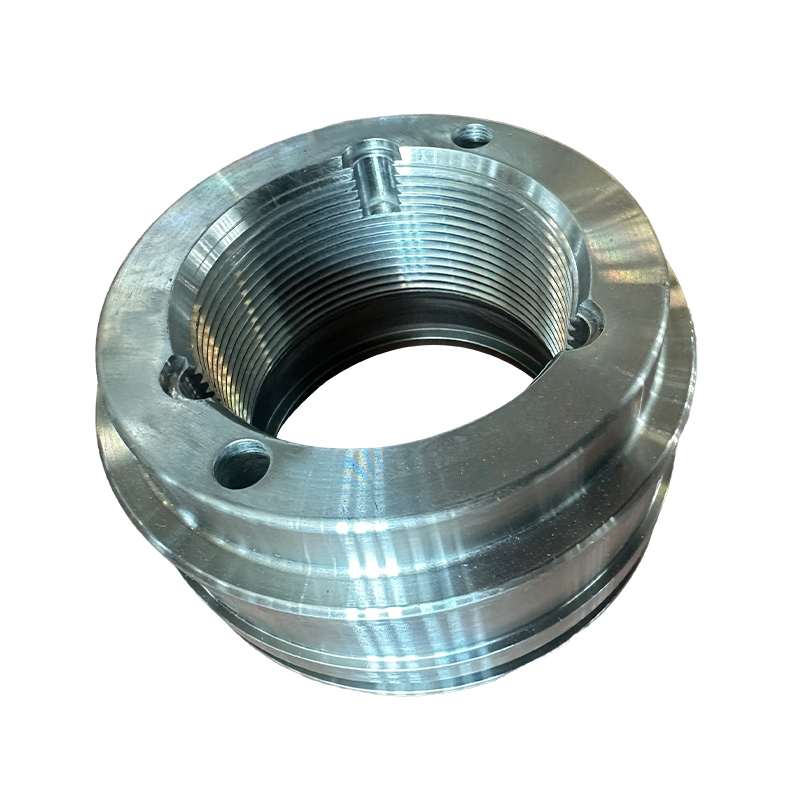

The precision of the manufacturing process also determines the actual performance of the clearance. The machining tolerances of the piston and cylinder liner must be strictly controlled, and the surface roughness must be moderate—too rough accelerates wear, while too fine impedes oil film retention. During assembly, measuring tools and operating procedures ensure that each piston and cylinder liner pair meets design requirements, preventing operational malfunctions due to individual deviations.

In addition, the operating characteristics of construction machinery also influence clearance setting. Equipment that frequently starts and stops, operates under heavy loads at low speeds, or operates at high loads for extended periods experiences more intense thermal cycling, placing higher demands on the thermal stability of the piston. Manufacturers must adjust the material formulation and structural design based on the equipment type and operating environment to ensure that the clearance maintains functional integrity under various operating conditions.

Ultimately, this gap isn't a fixed value; it's a physical state that evolves dynamically with time and temperature. It requires designers to possess a deep understanding of the material's thermal behavior, rigorous control of manufacturing precision, and a thorough understanding of actual operating conditions. During a cold start, the piston glides smoothly without any knocking or unusual noise; after warming up, it delivers ample power without any blue smoke or pressure leaks. This is the silent embodiment of the immense engineering wisdom behind this tiny gap. It silently carries the reciprocating motion of millions of times, safeguarding the steady beating of the mechanical heart under high temperatures and pressures.

The piston experiences dramatic temperature fluctuations during operation. During a cold start, the metal components are at room temperature and their dimensions are minimal. Once the engine is running, the high temperatures generated in the combustion chamber are rapidly transferred to the piston top and diffused through the skirt, causing the piston material to expand. The cylinder liner also expands due to heat, but its thicker structure and longer heat conduction path generally lead to slower expansion rates and magnitudes than the piston. Therefore, when designing the clearance, it's crucial to anticipate the differences in deformation between the two under different operating conditions. This ensures a thin, stable lubricant film is consistently maintained between the piston and liner, whether during cold engine startup or full-load operation. This reduces friction and ensures effective sealing.

To achieve this, strategies to mitigate thermal expansion are incorporated into the piston's structural design. The piston skirt often features a non-circular profile, such as an elliptical or stepped shape. When cold, it assumes a specific geometric form, but upon heating, it gradually converges to a perfect circle, conforming to the cylindrical surface of the cylinder liner. Some pistons also incorporate internal constant-range steel plates or feature shaped pin holes to suppress lateral expansion and make hot dimensions more manageable. These structural features directly influence the clearance setting—it's not simply a matter of fitting a cylinder and a hole, but rather a precise matching of dynamic form and static space.

Lubricant plays multiple roles within the clearance. It not only acts as a lubricant but also provides heat dissipation and sealing. Appropriate clearance allows the oil to form a hydrodynamic film during the reciprocating motion of the piston, preventing direct metal-to-metal contact. Furthermore, in areas where the piston rings fail to fully seal, the oil film temporarily prevents high-temperature combustion gas from leaking downward or oil from leaking upward. If the clearance is too large, the oil film can be easily breached by high-pressure gas, leading to blowby. If the clearance is too small, the oil film is difficult to establish, lubrication fails, and friction increases dramatically.

The precision of the manufacturing process also determines the actual performance of the clearance. The machining tolerances of the piston and cylinder liner must be strictly controlled, and the surface roughness must be moderate—too rough accelerates wear, while too fine impedes oil film retention. During assembly, measuring tools and operating procedures ensure that each piston and cylinder liner pair meets design requirements, preventing operational malfunctions due to individual deviations.

In addition, the operating characteristics of construction machinery also influence clearance setting. Equipment that frequently starts and stops, operates under heavy loads at low speeds, or operates at high loads for extended periods experiences more intense thermal cycling, placing higher demands on the thermal stability of the piston. Manufacturers must adjust the material formulation and structural design based on the equipment type and operating environment to ensure that the clearance maintains functional integrity under various operating conditions.

Ultimately, this gap isn't a fixed value; it's a physical state that evolves dynamically with time and temperature. It requires designers to possess a deep understanding of the material's thermal behavior, rigorous control of manufacturing precision, and a thorough understanding of actual operating conditions. During a cold start, the piston glides smoothly without any knocking or unusual noise; after warming up, it delivers ample power without any blue smoke or pressure leaks. This is the silent embodiment of the immense engineering wisdom behind this tiny gap. It silently carries the reciprocating motion of millions of times, safeguarding the steady beating of the mechanical heart under high temperatures and pressures.