How can we ensure the positioning accuracy of the bolt holes on the large flange of construction machinery parts to avoid loose connections after installation?

Release Time : 2025-09-10

Ensuring bolt hole positioning accuracy in large flanges for construction machinery components requires first laying a solid foundation during blank preprocessing. Large flanges are subject to heavy loads and constant vibration, and the uniformity of the blank material directly impacts processing stability. Leveling is necessary to eliminate warping, and aging is used to release internal stresses to prevent hole displacement caused by uneven material shrinkage during subsequent processing. Furthermore, the blank's reference surface must be precision-ground to remove oxide layers and surface defects. This ensures a flat and reliable positioning reference during processing, providing a stable foundation for precise bolt hole machining.

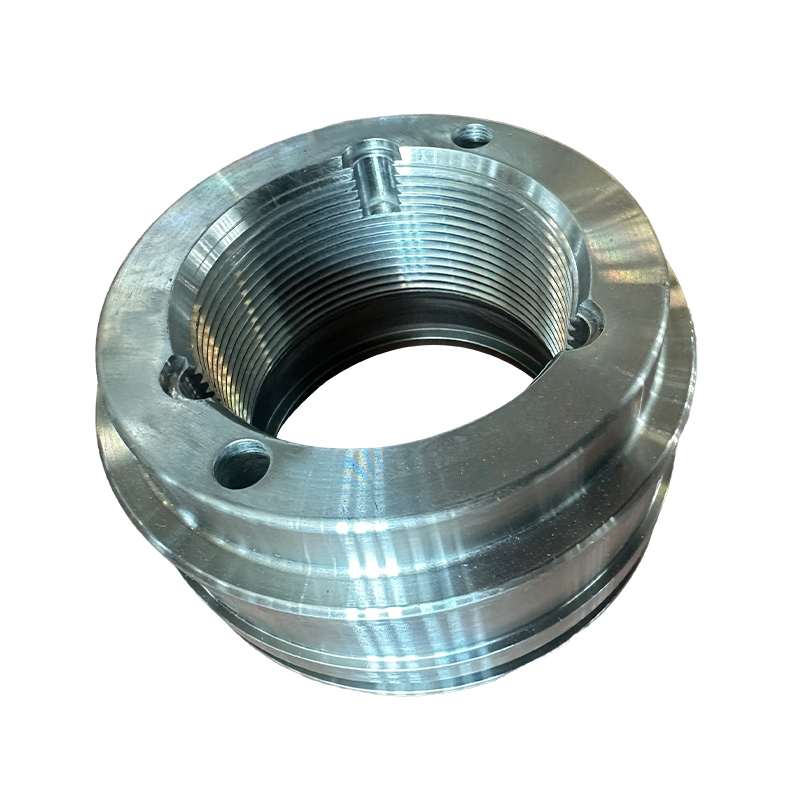

Debtal setting during machining is central to precision control. A unified machining coordinate system must be established, using the sealing surface and center axis of the large flange as the core reference. The servo drive system of the CNC equipment, in conjunction with a centering fixture, precisely positions the flange blank, ensuring that the center of the circumferential distribution of bolt holes coincides with the flange center. During machining, the axis of each bolt hole must be perpendicular to the sealing surface to prevent tilted holes from causing uneven bolt force during installation. Program control also ensures uniform hole spacing, ensuring balanced force during flange connection and reducing the risk of loosening caused by localized stress concentration.

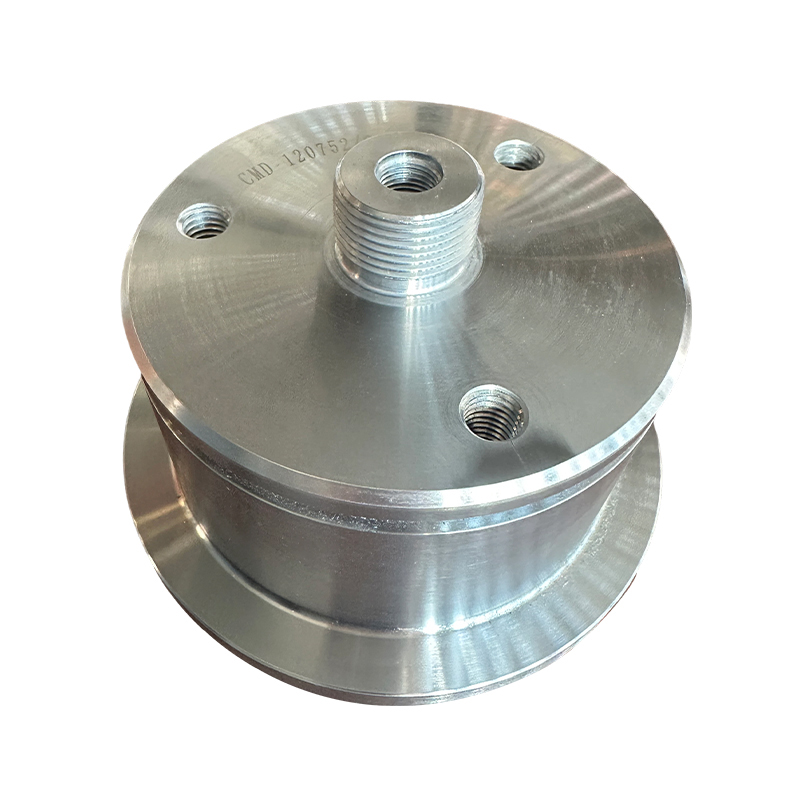

The choice of machining process directly impacts the stability of hole position accuracy. Specialized equipment such as CNC drilling machines utilizes their servo-motor-driven rotary indexing function to precisely control hole position indexing. Adjustable pneumatic grippers and centering pins securely hold large flanges of varying specifications, preventing deviations caused by workpiece movement during machining. During machining, automatic program generation automatically calculates hole coordinates based on the flange diameter and number of holes, reducing manual programming errors. At the same time, precise tool cooling and wear monitoring are emphasized to ensure consistent drilled hole dimensions.

Real-time inspection and correction mechanisms are essential. During machining, precise measuring tools are used to spot-check hole coordinates. Rotary inspection is used to determine vertical deviations, record the direction of deviation, and adjust machining parameters promptly. Completed flanges are thoroughly inspected for bolt hole position and diameter accuracy. Any out-of-tolerance holes are corrected through fine grinding to ensure that every hole meets design requirements and avoid uneven overall force due to deviations in individual holes.

Precise alignment during installation is crucial for ensuring accuracy. The use of locating pins and guide holes allows for quick alignment of flanges and mating components, avoiding deformation caused by forced assembly. Bolt tightening should be performed symmetrically from the center outward, ensuring uniform contact between the flange surfaces. Using torque control tools, the preload force of each bolt should be consistent to prevent plastic deformation caused by overtightening or gapping caused by overloosening, minimizing the risk of loosening during installation.

Optimizing structural design to prevent loosening can enhance precision retention. Designing countersunk holes or chamfers around the bolt holes, combined with locking nuts and elastic washers, increases friction and self-locking properties of threaded connections. In some scenarios, a transitional fit between the bolt hole and the bolt can be employed to enhance connection stability through a slight interference fit. Anti-slip grooves can also be applied to the hole wall to reduce bolt movement under vibration, extending the structural accuracy retention period.

Daily maintenance is also crucial for long-term precision maintenance. Regularly check the tightening of the bolts and the contact with the flange surfaces, clean any debris and rust from the holes, and retighten any loose bolts to the specified torque. If holes are worn or deformed, repair them promptly and replace flange components if necessary to prevent loosening of the entire connection due to local precision failure. Through continuous maintenance, ensure that bolt hole positioning accuracy remains stable throughout the life cycle of the construction machinery.